Chris Winslett joined RTX as general manager of Blue Canyon Technologies in September 2023. Formerly the program director for the Space Development Agency Transport Layer programs at Lockheed Martin, Chris brings close to 25 years of experience in the aerospace industry to Blue Canyon.

Prior to his position with Lockheed Martin, he was the director of programs Chris Winslett for OneWeb Satellites, a joint venture between OneWeb and Airbus. Chris also worked with Boeing for 17 years.

Good day, Mr. Winslett. Would you please tell us exactly what makes Blue Canyon Technologies different than other providers?

Chris Winslett

Chris Winslett

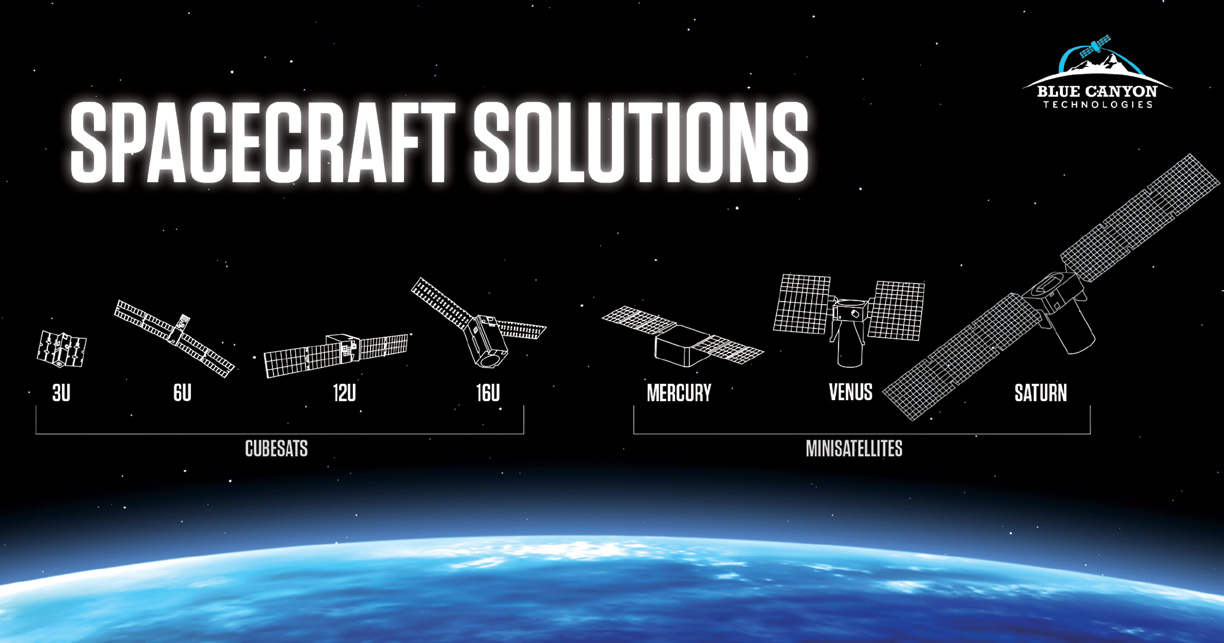

The Blue Canyon Technologies’ family of spacecraft offers end-to-end- solutions for unique mission needs, solving the toughest challenges in space. Our suite of seven small spacecraft ranges from a 3U CubeSat to an ESPA- Grande or equivalent mini satellite, providing robust power systems, secure data handling and resilient performance for defense, commercial and civil projects.

With 68 spacecraft launched to-date, our products are reliable, high- performing and flight proven. Our components and bus platforms have completed missions ranging from Very Low Earth Orbit (VLEO) to cislunar and interplanetary journeys.

What is the importance of having on-orbit heritage?

Chris Winslett

For more than a decade, Blue Canyon Technologies’ high-precision, technically-advanced solutions have disrupted the space industry by demonstrating how lower-cost small satellites serve as a complement to larger satellites in a number of arenas, and even a full replacement in others.

We have proven that this technology works. In fact, when it comes to small satellite solutions, we have unrivaled heritage.

Blue Canyon made its first flight hardware delivery in 2013, which means we have more than a decade of experience supporting missions for premier organizations including the U.S. Air Force Research Laboratory, NASA, MIT Lincoln Lab, the Johns Hopkins Applied Physics Laboratory and Colorado University.We have an impressive flight heritage of more than 90 cumulative years on- orbit for spacecraft, 151 years for avionics assemblies and 3,100 years of components.

For the last three years, as a subsidiary of RTX, our company has produced nearly 2,000 products each year, bringing us to the following lifetime milestones that include more than 2,000 reaction wheels, more than 1,400 sun sensors, more than 400 batteries, nearly 500 star trackers and more than 200 guidance, navigation and control systems.

We also have more than 150 flight spacecraft orders, ranging from our XB1 avionics to the 200-kg payload mass capability of our Saturn-class minisatellite, our line of spacecraft have supported every mission segment — from interplanetary exploration to weather mapping and SAR constellations with 24 / 7 Earth Observation (EO).

How are small satellites disrupting the traditional space industry?

Chris Winslett

At Blue Canyon, big discoveries start small. As the award-winning TROPICS mission has shown, challenging missions can be accomplished with small satellites. TROPICS uses our 3U CubeSat platform, resulting in a satellite that is 50 times smaller and 0.01 percent of the cost of previous weather-sensing systems that collect similar measurements.

Furthermore, the upcoming SPARCS mission intends to use a 6U CubeSat – roughly the size of a cereal box – to search for exoplanets around distant stars, performing the types of astrophysics research that is usually reserved for billion- dollar, monolithic spacecraft like Hubble, James Webb and TESS. However, thanks to Blue Canyon’s pointing accuracy and low-jitter reaction wheels, these types of missions are now much more affordable.

What makes Blue Canyon Technologies’ guidance, navigation and control systems unique?

Chris Winslett

The first launch of a Blue Canyon Technologies XACT product occurred in 2016 on the MinXSS CubeSat, providing one of the first three-axis, stellar-based arcsecond-pointing attitude control systems for the CubeSat form factor.

In the seven years since the first commercial off-the-shelf Guidance, Navigation and Control (GNC) system was delivered, Blue Canyon has nearly 100 GNC subsystems with on-orbit heritage and multiple other spacecraft supported by our individual GNC components. These missions have included numerous LEO satellites and constellations, the first interplanetary CubeSat, GEO and Lunar spacecraft.

How is Blue Canyon helping customers solve the toughest challenges in space?

Chris Winslett

In addition to our industry-leading pointing accuracy, Blue Canyon is where customers turn for solutions for thermal control, guidance and navigation and mission challenges.

For example, when DARPA and Northrop Grumman wanted to space-qualify a new type of Kapton membrane reflectarray antenna, they relied on Blue Canyon to manage the guidance and navigation challenges of controlling a large, deployable structure with a much smaller spacecraft — our Venus-class minisatellite.

Would you tell us more about how Blue Canyon is adapting standard products to meet unique mission needs.

Chris Winslett

We are bridging the gap between standard and bespoke. While many of our competitors focus on creating standard platforms with little or no opportunity for customization, or only building made-to-order spacecraft, Blue Canyon’s work lies between these two extremes, allowing customers to work directly with the system engineers and designers who build the product to adapt our standard suite of small satellites.

With the support of RTX, we have started maintaining an inventory of spacecraft components and structures on the shelf with prepared standard specification documents, analyses and statements of work, allowing us to bid projects quickly and be more agile as a company, decreasing customer lead time.

Our vertical integration allows for increased control of our supply chain, with all components and spacecraft manufactured within our 100,000+ square-foot satellite factory, which is specifically designed with the capability to handle large constellations of small spacecraft systems.

With high-volume manufacturing, highly integrated spacecraft buses and flexible ground software, every stage of our manufacturing process is designed to maximize payload mass and volume on-orbit while minimizing overall mission cost.

Blue Canyon remains as agile as ever and is ready with reliable, high- performing and flight proven products to meet all mission needs.