Packing a punch in GEO: The new breed of smallsats

A powerful new breed of satellites that are as much as ten times smaller than traditional geostationary spacecraft offer satellite operators a world of new possibilities.

Emile de Rijk

Until recently, it was received wisdom in the spaceflight sector that geostationary orbit (GEO) satellites are the size of a trucks, weigh up to 10 tons, take years to build, cost up to $500 million each and, to top it all, require a small fortune to launch.

These gating factors of geostationary orbit have historically made it too expensive for operators to expand broadband, 5G or television capacity to smaller regions, replace decommissioned satellites for declining (but still potentially profitable) services, add services incrementally to test or expand new markets, or even place an on-orbit spare as a backup.

No longer — while those bus-sized behemoths have their place, they are no longer the only kind of satellite that can shoot for GEO. Innovative, small satellites (smallsats) — of similar size to the ones that now dominate Low Earth Orbit (LEO) — are now starting to make their way to GEO, as wekk. This new class of smallsat offers telcos and broadcasters a new and highly cost-effective way to quickly boost geostationary capacity.

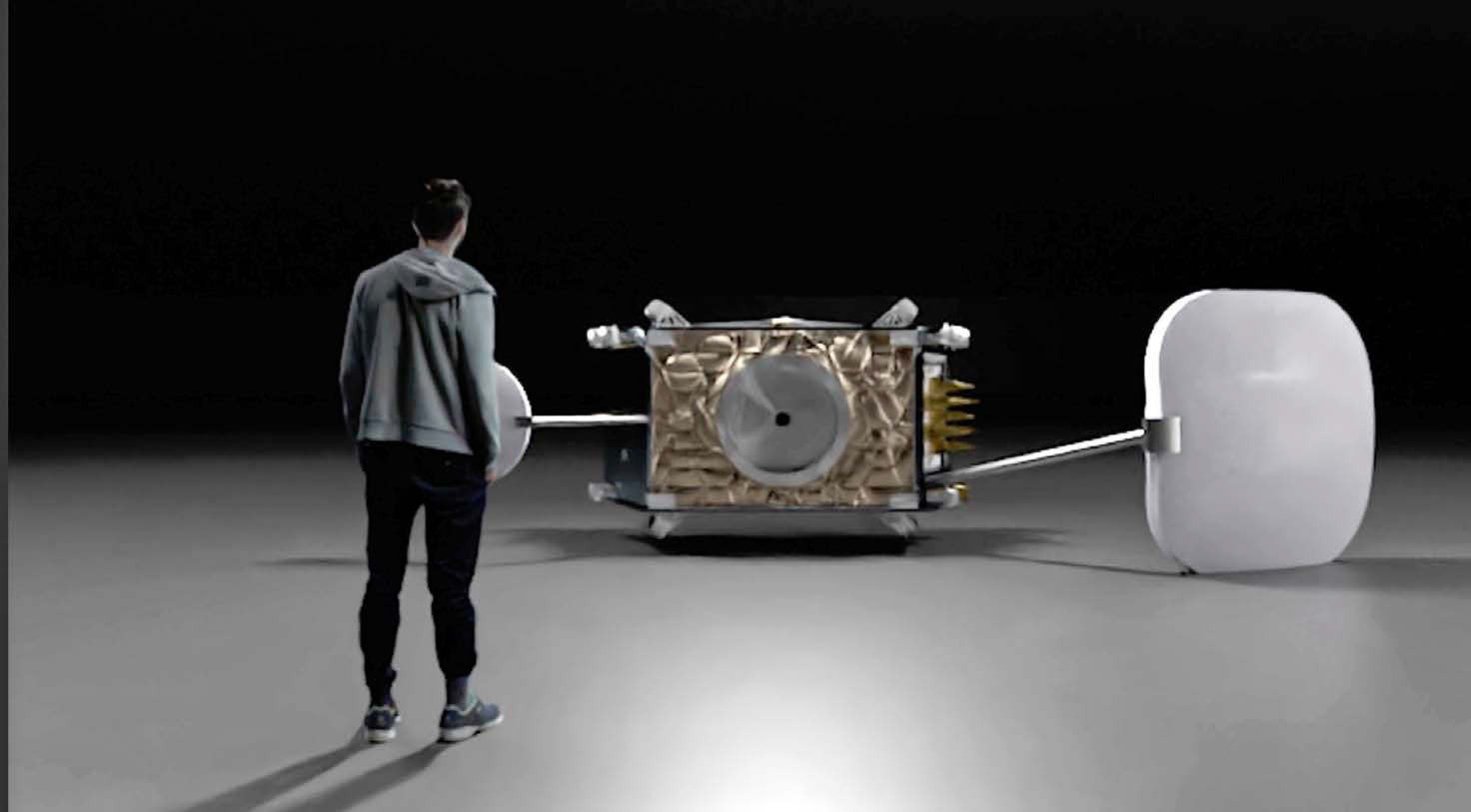

GEO smallsats are an emerging new class, and leading their way is the photocopier-sized satellite we’ve developed at SWISSto12. A 50 Gbit/s, multibeam, multichannel broadband satellite, each platform is packed with customized Radio Frequency (RF) payloads created using patented, 3D-printing techniques we’ve developed over the last decade. It’s exactly that precision 3D printing and the subsequent payload flexibility and performance it enables that means we can keep the 1.5 cubic meter satellite’s mass down to a mere ton.

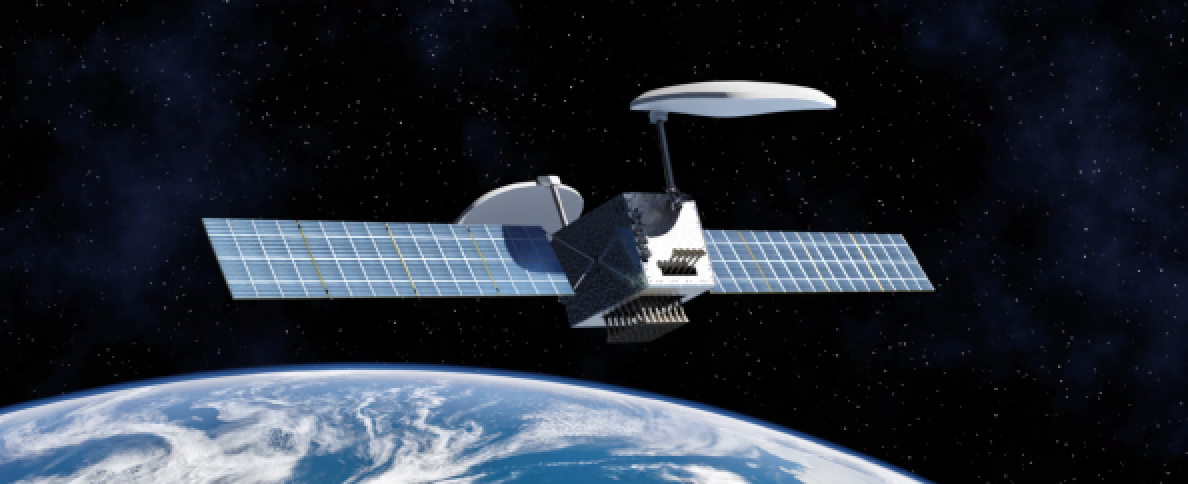

Our satellite, which we’ve called HummingSat, is compact enough to be launched to GEO on low-cost rideshare missions to Geostationary Transfer Orbit (GTO). Whether operators are providing 5G connectivity to cell towers in remote locations beyond fiber’s reach, beaming streaming video network services to cable headends, servicing airline inflight connectivity, or carrying emergency search and rescue messaging across the oceans — satellite operators now have a far less expensive, more flexible way to accomplish that goal. That’s good for people on the ground as it means reliable, fast-speed and low cost coverage wherever you are located in the world.

This isn’t blue sky thinking — it’s now a commercial reality. Two of the world’s largest satellite communications companies have ordered their own variants of the HummingSat spacecraft to augment their existing GEO assets over the next few years.

Specifically, Intelsat will launch a Ku-band (that is, 12 to 18 GHz range) HummingSat to serve regional TV markets in 2025, while ViaSat-owned Inmarsat will launch three, L-band (1 to 2 GHz) HummingSats in 2026 to strengthen that company’s radio-navigation safety services for 1.6 million mariners, 200 airlines, governments and space agencies.

HummingSat’s novel RF payload, on-orbit 35,000 km above Earth, will give coastguards, air traffic controllers, and other safety services more accurate GPS, increasing precision from 5 to 10 meters to as little as 10 centimeters.

Intelsat and Inmarsat are pioneers in geostationary communications. These orders — global satellite operators buying from an early-stage company such as SWISSto12 — are ground-breaking themselves, quite apart from the technology involved.

GEO is dominated by large, established players and no early-stage company has ever, in this manner, previously penetrated the GEO satellite market.

The reason we’ve been able to disrupt the payload as well as the wider GEO ecosystem rests with the company’s history: SWISSto12 began by 3D printing highly-reliable, precision, radiofrequency components — the “mustn’t fail” lifeblood of any satellite communications payload.

In 2011, I was studying a Ph.D. in Magnetic Resonance at EPFL — the Swiss Federal Institute of Technology in Lausanne, Switzerland. The project’s budget would not stretch to computer numerical control (CNC) based machining of the aluminium waveguides, antennas, signal routing systems and filters our MRI project needed. Instead, we began to experiment with 3D printing those RF components in aluminium — using a laser-melting, additive layer manufacturing (ALM) variant of 3D printing.

We found the ALM technology could, in fact, be encouraged, with a few (now patented) developments of our own, to print antennas and waveguides of the correct accuracy, surface finish and filtering precision — and at, roughly, half the price of CNC-made devices, as well.

We founded SWISSto12 and quickly identified that our novel 3D printed approach to RF components had transformative potential for the high-frequency bands used in satellite data communications.

Transformative because the 3D metallic structures required for high-frequency bands often have incredibly complex shapes, containing numerous hollow structures, cavities and waveguides. It’s somewhere between extremely challenging and outright impossible to machine the thousands of parts needed and to then assemble them. Innovation in RF payloads has, until now, been hamstrung by the limits of conventional manufacturing.

Our 3D printing techniques, however, free users from all those design constraints, while creating products with better all-round performance, mass, size, cost and lead times.

Fast forward to today and there are 20 of our customer’s satellites, in various Earth orbits, carrying at least 1,000 of our 3D-printed RF components on them — all space qualified against orbital temperature cycling as well as the severe shock and vibration of launch. It’s those spacecraft parts that have evolved into what is now HummingSat, so-called because we’ve named it after the hummingbird, because this bird is tiny, fast-moving and agile and yet hovers beside a flower like a satellite on the geostationary ring.

The overarching idea behind HummingSat is to provide operators with a spacecraft that’s anywhere between three to 10 times lower in mass, size and price than traditional GEO satellites.

However, the most important of those factors is price, as it means operators can invest in an emerging market, allowing them to incrementally increase capacity without spending vast sums of critically needed funds.

HummingSat also allows operators to replace ageing satellites in GEO slots where they still produce a lucrative return, but where earnings simply don’t justify a full-scale, ten-ton GEO asset. In short, HummingSat opens up business cases that would otherwise go unaddressed by operators relying solely on conventional GEO satellites.

Let us not also forget the natural advantages of GEO: unlike the massive, multi- thousand-satellite constellations needed for constant ground comms coverage in LEO, it only requires three satellites to cover the entire Earth from GEO.

Indeed, the increasing density of LEO constellations is raising significant concerns over the navigability of LEO by manned spacecraft and of uncontrolled re-entries by LEO satellites, potentially impacting commercial aviation.

Therefore, be sceptical of claims that LEO constellations are the best way to provide high-speed connectivity from orbit. GEO has flourished for more than 60 years — and now this new breed of compact, cost-effective, ridesharable GEO smallsats are set to make it a hive of innovation — once again.

swissto12.com