Electronically Steerable Antennas (ESA) represent one of the more exciting advances in the satellite industry.

Flat Panel technologies that enable ESA is one of the specific areas garnering tremendous interest and many ventures are leading the way toward the next evolution in SATCOM antenna innovation.

No technological advance is smooth, all are challenging, and ESA flat panel technologies are no different in that aspect. The industry has had to — and is still — dealing with serious obstacles that must be overcome in technology and unit production that have adversely affected potential and actual users. These issues boil down to the cost of addressing size, weight, bulk and power consumption — the infamous SWaP challenge.

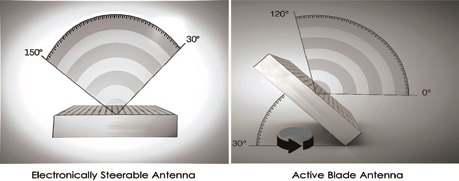

Full ESA antennas, where azimuth and elevation are electronically steered, use a myriad of elements including RF and phase-shift chips to coordinate antenna moving and tracking. Depending on a terminal’s size, many of these antennas have a significant number of chips, which significantly drives up acquisition costs for the customer as well as challenges engineers to ensure they operate properly and efficiently. The large number of chips also consume a lot of power, create a great deal of heat that requires heat dissipation technologies and have lackluster RF performance

With ESA antennas using different panels for Tx and Rx, a terminal’s structure is bulky, large and heavy. Separate panels take up a great deal of space and add significantly more bulk and weight to their structure. Separate panels necessitate a unit that is large and not easy to create, aerodynamically — that damages potential opportunities where aerodynamic contours are a mission requirement. Additionally, ESA antennas are not built to support wide bandwidths.

An additional issue plaguing traditional ESA architecture is that Look Angles are limited when the antenna points outside its limits, leading to signal weakness. ESA antennas have challenges supporting low elevations. For instance, at <20 degrees, there is a general degradation of 12 dB. For users seeking better signal strengths, it becomes difficult to move forward with this type of flat panel technology.

To address these issues, and more, flat panel antenna technologies require a change, something that offers better and different technological methodologies.

One area of special interest for flat panel enthusiasts is miniaturization or micronization of elements that also do not sacrifice quality to ensure that all critical operational requirements are met. Leading this movement to micronize military and commercial SATCOM antenna technologies is Get SAT, an innovator in small, lightweight satellite communication terminals. The company’s micronized, integrated terminals specifically target SOTM (Satellite-On-The-Move) applications: in the air, on the ground or on the seas.

Instead of creating an all ESA antenna (two dimensional—2D), the company has created a one dimensional (1D) ESA: Active Blade. Active Blade’s technologies reach beyond and mitigate the challenges mentioned earlier in this article. The firm’s highly efficient antennas cover a 2 GHz bandwidth to support commercial and military Ka-bands. The terminal comes in multiple sizes to accommodate the needs for secure and mobile connectivity applications.

The 1D architecture has a single motor, azimuth is mechanical and elevation is electronic, which enables the terminal to be significantly lighter and more efficient than competing product. A 1D unit has a far lower physical, aerodynamic profile in comparison to fully mechanical terminals. In addition, the company’s miniaturized antenna hardware and its software algorithms ensure that all connections and pathways within the architecture exceed industry standards.

The Benefits

Without the need to electronically control antennas in two dimensions, Active Blade employs fewer chips that are all high-performance. Also, by creatively using other components such as RF chips, the terminal boosts the system’s overall efficiency to more than 60 percent, almost a two-fold improvement when compared to other ESA antennas on the market, as well as providing more G/T and EIRP for the given area.

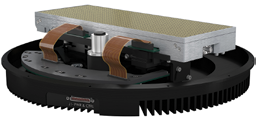

Get SAT’s Active Blade, folded.

Fewer chips also means reduced power consumption, streamlined power sources and a decreased need for heat dissipation technologies. Having fewer cooling techniques leads to fewer parts and additional space, which leads to an assembly that is further micronized.

With mobility, weight, size, advanced aerodynamics and low-profile requirements at the top of client requests, Active Blade takes advantage of Get SAT’s patented, fully-interlaced, InterFLAT flat panel technology that transmits and receives signals on the same panel. InterFLAT’s dual capabilities significantly decrease antenna (and thus terminal) size, bulk and weight creating an advantage over traditional ESA antennas that use different panels for Tx and Rx. An ESA unit with separate panels needs to be four times the size of Active Blade just to reach a similar performance.

Regarding Look Angles, Active Blade’s micronized architecture enables the antenna to reach more angles that see the entire sphere,

360 degrees azimuth and 0 to 90 degrees elevation wherever the satellite resides.

Lastly, as a fully integrated terminal, clients save significant effort, time and resources. They can simply connect the power and an IP connection with data is at the ready.

Beyond Active Blade, Get SAT is targeting an additional growth area: L-band SATCOM applications. Under the Ultra Blade brand, this versatile, super low-profile, L-band antenna will be compatible with various land mobile L-band terminals and L-band satellites.

Get SAT Active Blade versus ESA.

Ultra Blade will become the market’s leading, complete, all-planes ESA antenna with no moving parts. The antenna’s streamlined physical characteristics and technical achievements will change the future of mobile broadband SATCOM.

The number of elements used are reduced when compared to K-a and Ku-band offerings. The company is able to develop an extremely flexible, efficient and powerful full L-band ESA antenna. Ultra Blade’s L-band antenna passes the industry’s current maximum data rate by reaching more than 2 Mbps via a 500 Khz channel. No terminal has ever reached that level in the L-band sphere.

Expanding Get SAT’s SOTM L-band applications, Ultra Blade will combine unbeatable SWaP all in a single package of less than 5 lbs. (2.4 kg). The company expects this will be an innovative product that will change the physical make-up of L-band terminals for the better — Get SAT is excited by the opportunities Ultra Blade will

offer customers.

Get SAT, with the firm’s technologies and innovations, plans to be a leader in providing creative solutions to push the industry further and farther with antenna innovation.

www.getsat.com

Kfir Benjamin is a business executive with more than 16 years of international experience in multiple technological disciplines. Kfir has lived and worked in various international locations working in various technological and business positions to conduct worldwide, multi-cultural business in North-America, Europe and Asia-Pacific. Previously, Kfir worked in several senior business development and sales positions at Roche, Surf Communication Solutions (U.S.), Microwave Networks (U.S., UK), and Helios communication (UK, China, Israel). During his military service, Kfir served as a Captain in the IDF UAV unit.