Advantech Wireless Technologies

Much has been written elsewhere about the “year of the pandemic”. While COVID-19 impacted Advantech Wireless Technologies (AWT) in 2020 with near term volatility, the long-term outlook is exceptionally robust.

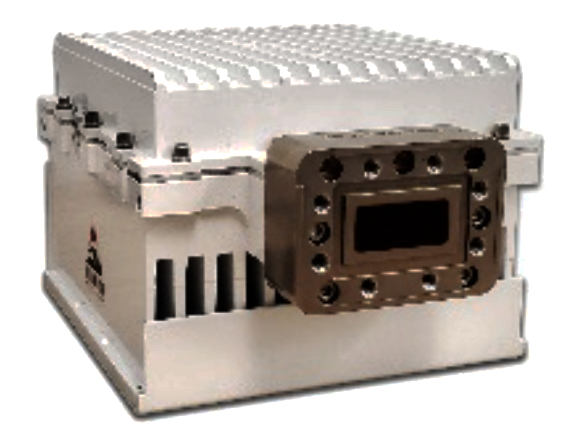

The Advantech STAN series of converters.

Despite the COVID-19 pandemic and related economic conditions in 2020, Advantech remained fully operational around the globe. As a supplier to leading global communications companies, governments and their agencies, and the militaries of many NATO countries, our highest priorities were keeping our employees safe, ensuring our ability to serve our customers during this difficult time.

The AWT sales and engineering teams remained available to support customers globally. Some of our most significant product launches occurred this year, with more to follow in 2021.

With so much enthusiasm generated by the promise of LEO, we released our new line of STAN Frequency Converters (Satellite Tracking and Navigation), designed specifically for applications that require two-channel coherent signal processing, such as telemetry, tracking and control (TT&C) and Low Earth Orbit (LEO) Tracking & Navigation. STAN’s ability to provide correction offsets for LEO satellites makes them particularly suitable for navigation and location services.

AWT commenced production of our new Summit II high-power, soft-fail SSPA systems for deployment in early 2021. Built on a new, state-of-the-art control platform, Summit II can reach extremely high levels of RF output power, while providing a level of system availability that rivals anything in the industry. With microwave passive components being a major staple of the AWT product portfolio, high-density, low-loss RF combining structures are the basis for our new line of Ka-band SSPAs.

Speaking of microwave passives, AWT worked with the members of the C-band Alliance, including Intelsat, SES, Eutelsat and Telesat to develop a line of 5G interference reject filters that allow 5G operators and satellite operators to cohabitate the C-band portion of the RF spectrum.

Advantech’s SpiritX BUC.

For companies that would rather put distance between their carriers and the 5G traffic, we have a complete line of INSAT products that will take you up to the 7 GHz end of the band. AWT’s ever-popular S-band amplifier has been expanded to include L/S-band, with single boxes delivering power levels up to 700W — or integrated into phase-combined systems that can deliver thousands of watts of redundant power. Our newly released Spirit-X BUCs produce 25W and 50W from a small compact package.

The team at Advantech is proud to be a founding member of the new SSPI Canada Chapter. With Canadian expertise currently growing in the fields that cover LEO, MEO and GEO satellites, Space Robotics, Sensors, 5G and Artificial Intelligence (AI), the launch of the new SSPI Chapter is a great opportunity to strengthen our collaboration within the Canadian Space ecosystem and the SSPI Chapters across the globe. Satellites have become an integral part of life and, therefore, there will always be commercial and government opportunities. Customers’ increasing need for stable connectivity and throughput requires a level of ubiquity that only satellites can deliver.

Fortunately, there are many new technologies on the horizon that will fulfill the needs of the consumer. As a Company that thrives on technological challenges, Advantech Wireless Technologies has adapted by maintaining strong technological leadership in order to satisfy the requirements of the entire SATCOM Industry.

Author Cristi Damian is the VP of Business Development for Advantech Wireless Technologies. holds a Master’s degree in Electrical Engineering and initially held roles as a hardware engineer at various high-tech companies. He joined Advantech Wireless in 1995 and has held executive positions including in Operations, Manufacturing, Sales, and Engineering. His expertise is centered on Solid State RF technology for Space Applications, and complex integrated networks design.

Alpha Data

For Alpha Data — and the world as a whole — 2020 has been full of unexpected and unprecedented challenges. While the year has brought uncertainty and concern for the safety of our family and colleagues, it has also provided the impetus to evolve the way we work and to plan for a future where high-speed communication is essential to everyday life.

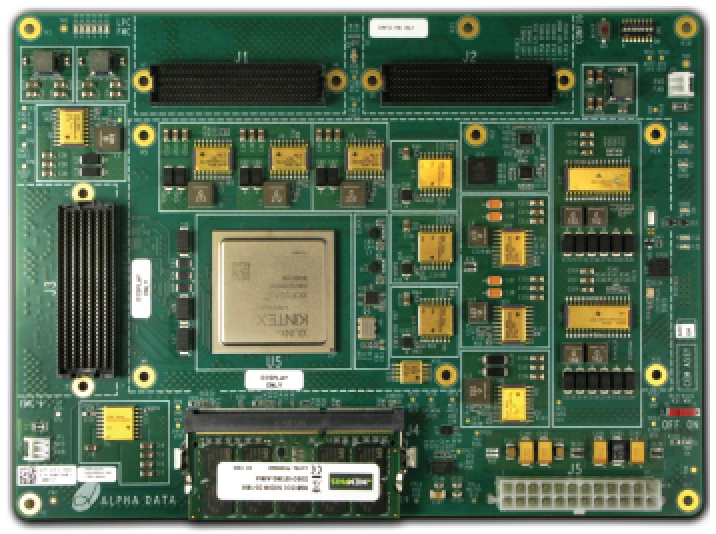

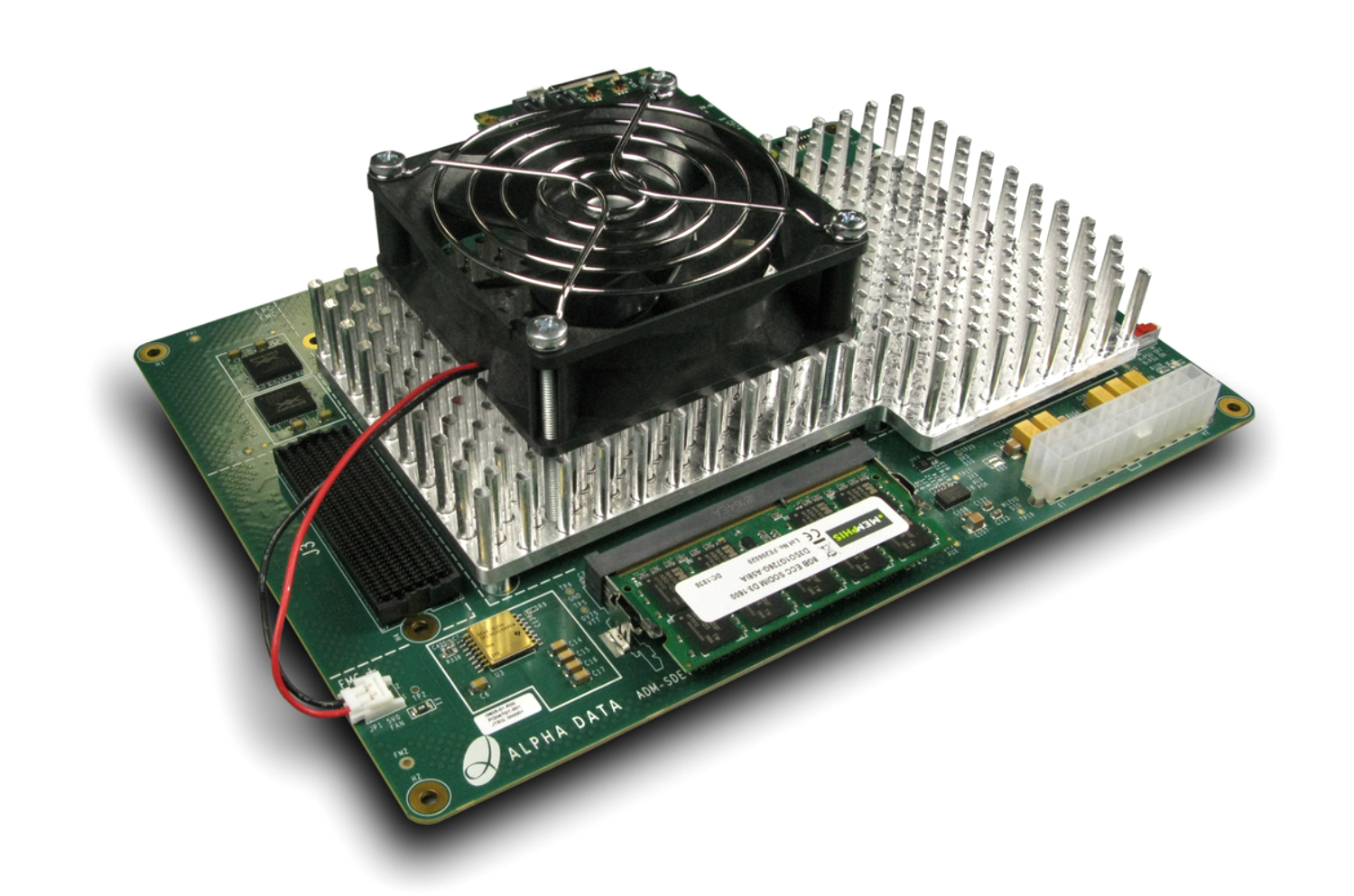

Space Development Kit baseboard.

Working with a flexibility imposed by the unfolding COVID-pandemic, Alpha Data started the year by launching a new radiation-tolerant space development kit in collaboration with Xilinx and Texas Instruments. With more than 20 years of experience working with Xilinx’s Field Programmable Gate Arrays (FPGAs) — essentially reprogrammable integrated circuits— Alpha Data have a long experience of developing leading-edge products based on the latest advances in silicon engineering from Xilinx.

This latest product incorporates the Xilinx™ Radiation Tolerant Kintex® UltraScale™, the world's first 20nm space-grade FPGA. The new device offers a offers a tenfold improvement in digital signal processing performance compared to previous generations of devices, making it ideal for payloads incorporating onboard machine learning. As machine learning becomes more widespread in dealing with the torrent of data produced by satellite remote sensing, the ability to use machine learning to pre-process and filter huge quantities of data will give space companies a competitive edge.

Alpha Data’s Space Development Kit helps space companies gain this competitive edge by providing the support needed to test the hardware and software setups incorporating the Kintex UltraScale. Following the successful launch of the product, Alpha Data are continuing to develop example applications for the Space Development Kit, enabling customers to build on proven designs and reduce their own development cycle. Providing ongoing technical and design support is one of Alpha Data’s key strengths, and the company’s engineering team has a proven track record of assisting customers as they develop rugged aerospace products.

The launch of the space-resilient development kit is the first step in Alpha Data’s larger move into the NewSpace market, with builds on many years of providing technical products on to aerospace primes and research organisations such as NASA’s Jet Propulsion Laboratory. Alpha Data brings a combination of highly skilled and knowledgeable engineers as well as the ability to modify off-the-shelf components to produce rugged designs suitable for deployment in harsh environments.

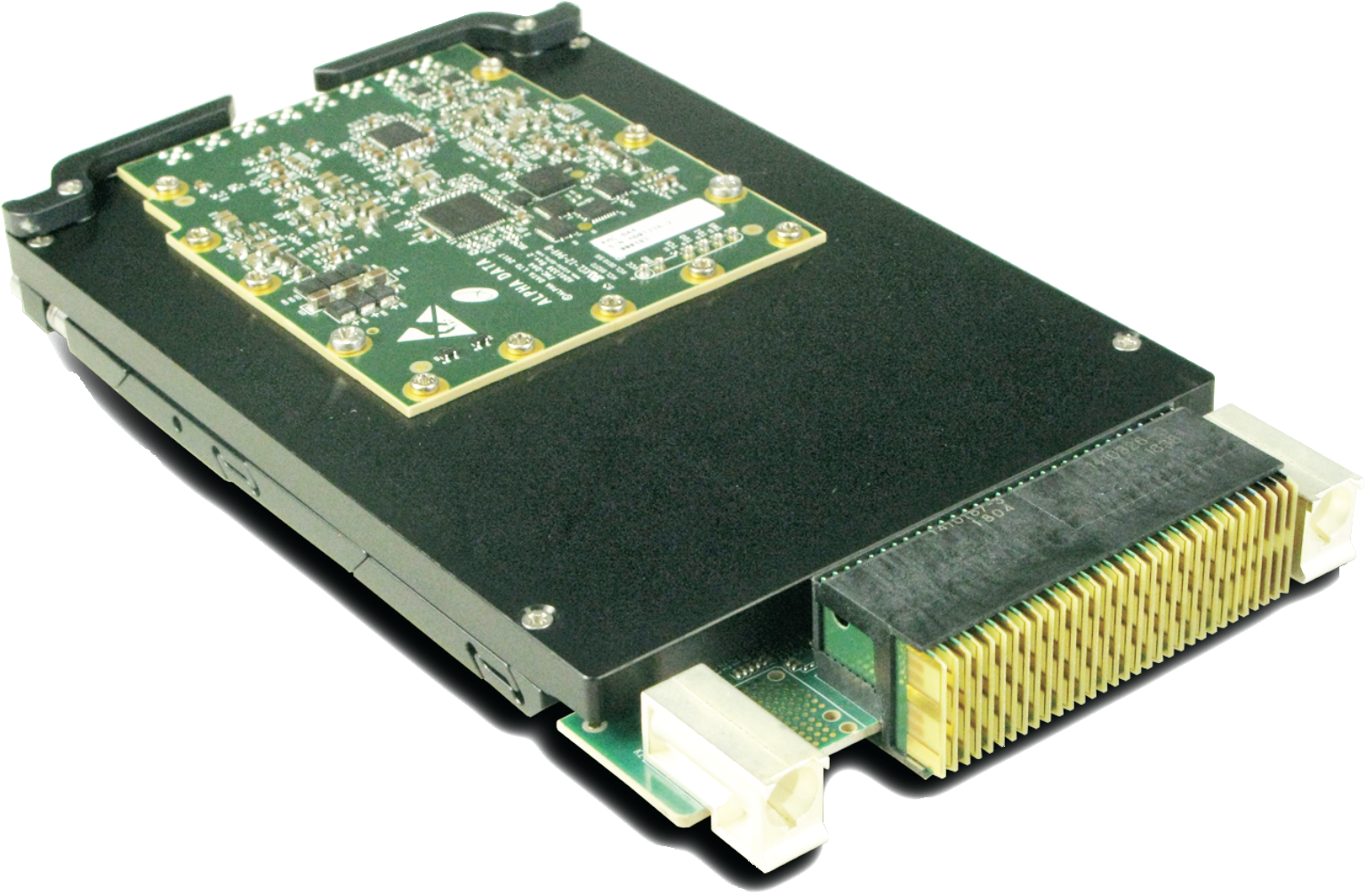

ADMVPX39V2 Highspeed Smart Switching

ADMVPX39V2 Highspeed Smart Switching  ADA-SDEV-KIT2 Kintex UltraScale Space Development Kit.

ADA-SDEV-KIT2 Kintex UltraScale Space Development Kit.

After the successful product launch despite the vicissitudes of 2020, Alpha Data’s plans in 2021 are to further enhance the space development board. Two upgrades currently under development are the integration addition of Ethernet support for MicroBlaze processor and integrating integration of Alpha Data’s CameraLink IP, which was successfully used for Hyperspectral imaging with the JPL FLEX compression core. The expansion of the space development board is being enabled by one of Alpha Data’s core strengths: the ability to quickly customise designs to meet customer requirements.

As well as working on the space development board, and despite working largely from home during the pandemic, Alpha Data engineers also completed the design and manufacture of our latest product, the 9Z5 Ssystem- on-M module. The 9Z5 — or ADM-VPX3-9Z5 to give it its full name — was developed in collaboration with Xilinx and Texas Instruments and is also an industry first. The 9Z5 is an off-the-shelf product that has been designed to military specifications throughout and is suitable for all stages of a project, from development to deployment. The stringent requirements driving the development of the 9Z5 mean the device is innately resilient and rugged — perfect for applications including space and high-altitude sensor processing.

The key feature of the 9Z5 is another cutting-edge Xilinx product, the "XQ" Defense-Grade Zynq UltraScale+ multiprocessor system on a single chip. This innovative Xilinx device features four tightly integrated processors as well as adaptable programmable logic and hardware specially designed to accelerate digital signal processing — features all useful for remote sensing and future Earth Observation (EO) satellite applications.

Another feature that makes the 9Z5 even more attractive for space applications is the compliance with Xilinx’s recently announced ‘LVAUX’ mode. Unveiled in 2020, this mode provides protection against a class of radiation-induced effect in electronic devices — single event latch-up. The effects of radiation on electronic devices is a critical factor affecting the processing power available on satellites — making the LVAUX mode a significant asset for high-altitude and space applications. Alpha Data’s '9Z5 has been designed to be fully compatible with the LVAUX mode. This added level of radiation tolerance, coupled with an extremely flexible interface, make the 9Z5 well suited for NewSpace applications in harsh radiation environments.

Whether it’s the radiation-tolerant space development kit or the space-ready 9Z5, Alpha Data’s 2020 products are perfectly suited to the growing NewSpace market. As businesses adapt to the post-COVID world, Alpha Data’s engineers are ready to support customers looking to quickly develop space-ready designs using very best in reconfigurable computing.

Despite the challenges of a turbulent year, Alpha Data is well-positioned going in to 2021, having navigated the uncertainties of 2020 with our usual flexible and agile approach to doing business. Whether in the office or at home, in our Edinburgh HQ or US base, Alpha Data’s team of highly skilled engineers have successfully spent another year providing customers with high-reliability, state-of-the-art solutions for compute intensive applications.

Author David Miller is a Chartered Engineer and Managing Director of Alpha Data Parallel Systems, a leading provider of FPGA based accelerator solutions to the Aerospace and Defence market. David has 30 years of experience in high-performance digital design. He and his team specialise in helping customers to define and realise their requirements - whether that be with an off-the-shelf or a fully customised product.

Aurora Propulsion Technologies

The bubbling New Space ecosystem has, in recent months, gained significant momentum. This is especially true in Finland, were a number of new industry players are gaining momentum.

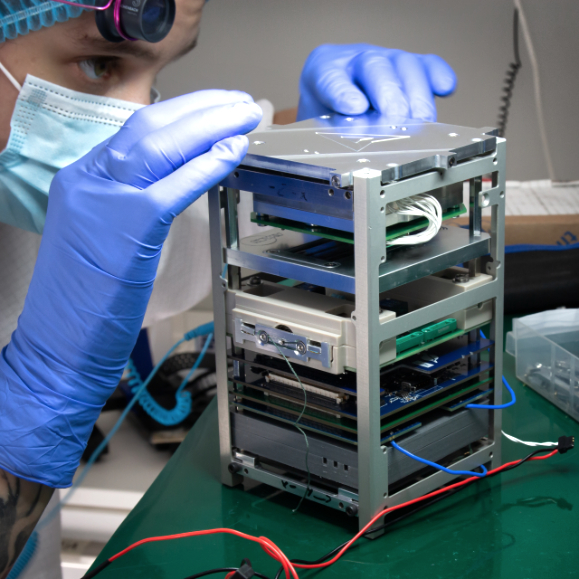

Photo of the AuroraSat1 smallsat, which is due to launch

in December 2020. Image is courtesy of the company.

With peers such as Iceye and RSL, Aurora Propulsion Technologies (APT) has recently also moved up the steps to establish space presence with its inaugural flight scheduled for December 2020. Aurora uses the same solar plasma wind that created the northern lights to propel spacecraft.

In addition to the solar wind driven electric sail development in progress, the company boasts the Aurora resistojet thruster modules and the plasma brakes for de-orbiting.

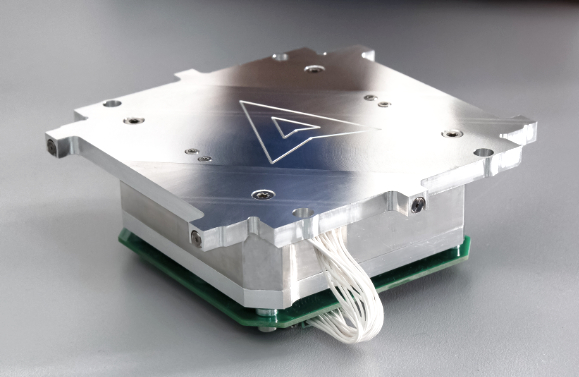

Aurora Propulsion Technologies’ micro-thrusters are hot gas thrusters using water as a propellant. The smallest thruster module in the product portfolio weighs only 34 grams, with a full tank of propellant. Larger units pack 6-12 thrusters and weigh 250 to 1200 grams to support different mission profiles and satellite sizes.

Even though the devices are small, light and power shy, they pack a punch, with factory set maximum thrust between 1-10mN and a throttle to tone it down in flight. This allows the use of the thrusters in both cube and small satellites up to 150 kg in mass.

Typical use cases include, attitude control, detumbling, collision avoidance manoeuvres and small orbital changes. With larger multi-thruster units precision navigation operations, such as docking missions are possible.

For propellant-less propulsion, the company offers its Plasma Brake. The Plasma Brake is a micro-tether-based product that uses an electric field to interact with low earth orbit plasma to slow down the satellites. Its main mission is to ensure launch regulation compliancy by enabling end-of-life de-orbiting of satellites.

The Plasma Brakes’ speciality is the ability to fit the system with a dead-mans’ swich to allow the de-orbiting of satellites that have lost their ability to operate otherwise. The Plasma Brakes work in orbits up to 1000 kilometres high and with satellites up to 1000 kg in mass.

APT has positioned its portfolio to support the growing satellite industry from early stage experimental satellites to small satellite constellation players. The technical parameters of the products put them ahead of ion propulsion in thrust and speed of operation and ahead in efficiency to the standard cold gas systems used traditionally in attitude control.

The Aurora Resistojet Module (ARM) a sixthruster reaction control

module for cubesats is Auroras’ first commercially available product.

The combo of capabilities allows for a uniquely wide mission portfolio for satellite operators. In effect, the systems allow for a large part of propulsion needs to be integrated in to one module, simplifying the building of satellites and small spacecraft.

In retrospect, 2020 has been super year for Aurora Propulsion Technologies and its team. The firm’s technology was productized, built and tested ready for flight in just five months. Additionally, the company built an In-Orbit- Demonstration satellite with its partner SatRevolution in record time.

Auroras’ CTO Perttu Yli-opas said, "I'm very proud of the Aurora team that have completed the design, development and build of AuroraSat-1, in such a record time."

AuroraSat-1 has a launch date set for December 30 on a SpaceX Falcon 9 rocket from Cape Canaveral. The satellite will fly the Aurora Resistojet Module (ARM) with a six-thruster configuration. In addition to the thruster module, the satellite will fly two Plasma Brakes to verify the tether deployment technologies, as well as the deorbiting simulation systems it has developed.

Even though only kick-starting its marketing and sales activities in late 2020, Aurora managed to log its first sales by midyear, taking the company from the technology development phase to the commercialization phase. This early start of customer revue was a positive surprise amidst the Covid-19 situation. It is also good base to continue growth in 2021.

In 2021, APT plans to complete the on-orbit test campaigns, first for the Thruster module and later for the Plasma Brake and the Lower Earth Orbit (LEO) plasma measurements to verify the simulations the company uses for de-orbiting calculations. With the test data and experiences from the test manufacturing, the company will further develop and optimize the technologies for large volume production.

Over the course of 2021, the company is also looking to complete a further demonstration flight for a larger satellite variant of its thruster products. Work will also be done to completing design optimization if the modules to support several additional control bus and frame variants for its customers.

A deep space variant of the thrusters is also in the plans, with an eye toward near future moon or planetary missions. These developments will pave the way for the companies anticipated electric sail development.

Together with the technological development, the company is developing its productions capabilities during 2021 to provide one of the fastest delivery times in the industry. Over the year, Aurora Propulsion technologies plans to actively grow the firm’s sales network by engaging new partners to support local markets in this exciting industry.

Shaking the Space Industry

Aurora Propulsion Technologies derives its product focus from the trends that drive the new space industry.

The key driver is the emerging standardization of form and launch structures, as well as the increasing launch capacity, modularization of design and emergence of industry supply chains.

These drivers have kick-started companies to dream of private constellations which, in turn, drives miniaturization to enable multiple simultaneous launches as well as pushing down the cost of launch of single satellites.

As a result, the average size of satellites has dropped hundreds of kilograms over the last ten years to land at just above the 100 kg mark in 2020.

More and more teams are able to join the game, allowing for a plethora of new and innovative use- and business cases to evolve in the industry.

It is reasonable to say that this massive volume growth will transform the industry dynamics, just as the car industry was transformed by Henry Ford a hundred years ago.

At the same time, the funding schema finds the space industry changing from being predominantly space agency-driven to a majority of funding being raised from private capital. This industry clearly is gaining the momentum to reach the stars.

Author Roope Takala is the Chairman and CEO of Aurora Propulsion Technologies and he is an experienced business and innovation leader with a background in orporate research leadership and strategy. He possesses 25 years in the Telecom and high-tech industry business development areas. With a background in Nokia, CERN, MIT as well as the founder of several start-ups, Roope has experience building companies within high tech. He is also the author/editor of the book “Product Concept Design.”

AvL Technologies

Is 2020 over yet? From a business perspective, 2020 has been a reasonably good year. From a personal perspective, it’s been a year of unknowns, sweeping changes and never-ending uncertainty.

AvL’s Model 2015 2.4m antenna.

Many of us were attending the Washington, DC, satellite trade show when the Covid-19 pandemic was declared and large-scale events came to a grinding halt. The show ended a day early and left exhibitors scrambling; however, we figured things out. We packed our antennas and shipped them back to North Carolina and then flew back to the comany headquarters to determine how to operate in the “new normal.”

AvL Technologies has remained open during Covid — the company is a recognized member of the Defense Industrial Base (DIB), which is a part of the Critical Infrastructure Sector, as determined by the Department of Homeland Security. As a member of the DIB, AvL Technologies is exempted from mandatory closures brought on by the pandemic. Manufacturing production has continued throughout the crisis and AvL has maintained the firm’scommitments to our clients.

Though we remained open, many things changed. First and foremost, our operations were dramatically altered to ensure the health and safety of all employees. Some personnel began working remotely and employees who work in our production facilities started observing strict safety measures that included wearing face covers, frequent handwashing, maintaining six-foot distances from each other at all times, frequent sanitizing of shared equipment and holding meetings via phone calls or outside with distancing. This was our new normal — the company remained efficient and productive thanks to the collective, positive attitudes of the firm’s employees and their commitment to keeping themselves and others safe.

AvL’s growth continued during 2020, though it slowed a bit. By the end of the year, the company had grown to 260 employees and this growth was reflected in new engineering capabilities, new prototyping capabilities, a new program management team, expansion of the information technology team, expansion of the electrical systems team, and expansion of the customer service team, to include a depot for a key customer.

We added two executives to the leadership team — Larry Watts, VP of Programs who’s developing and building a strong Program Management office with a focus on customer satisfaction, and Dr. Hamad Alsawaha, Senior Antenna Systems Engineer, who is leading AvL’s design and development efforts on many antenna products, including electronically steerable array (ESA) antennas.

AvL’s 1.35m Manual FIT ARSTRAT antenna with Matt Buckner.

AvL’s continued growth sparked the need for additional information technologies expertise and we added David Cox, a network engineer, and Andrew Cartwright, a cyber security specialist.

We were excited and proud to complete the new 2.5m Model 2510 ruggedized, low-PIM (passive intermodulation) and high-wind operations trailer-mount antenna. The antenna supports Ku-, Ka- and X-band and is certified Low-PIM (multi-carrier) for X-band at 2 x 200 Watts.

The antenna’s many certifications include MIL-STD-461 CE102 Conducted Emissions Compliance, MIL-STD-461 RE102 Radiated Emissions Compliance, MIL-STD-461 RS103 Radiated Susceptibility Compliance, IEC 61000-4-2, Part 4.2, Test Level 4 Electrostatic Discharge compliance, MIL-STD-810G Compliance, Munson Road Tested, Intelsat IESS Type Approved, and ARSTRAT Compliance.

Under an accelerated customer schedule, AvL completed this antenna with a full spectrum of enhanced, certified military communications capabilities that are additionally certified to support mission requirements designated for the most challenging and hostile environments. These capabilities can be provided ala carte, tailored to unique customer needs.

AvL’s 1.2m Model 1030T antenna.

We also rolled out several new products during the DC show, including AvL’s new Model 2015, 2.4m axi-symmetric antenna that is ultra-lightweight and packs into two lightweight cases plus RF kits. The 14 piece carbon fiber reflector is designed to operate in X-, Ku- and Ka-band, with new quick-change feeds and RF kits. The antenna is modular and flexible with numerous RF equipment options, and it supports RF or modem peaking.

This manual operation antenna functions on an aluminum space frame, which enables quick set-up and pack-up. Once the antenna is set-up, a simple, user interface computer assisted pointing assist tool is available for satellite acquisition.

The updated 1.35m Flexible Integrated Terminal (FIT) received ARSTRAT certification this year and offers a small package with big gain. This flexible, user-defined terminal platform has a 12-petal reflector and an integral tripod for a small pack-up in two IATA-compliant checkable cases. This antenna can be operated manually or upgraded to motorized operation with auto-acquisition. The terminals operate in X- , Ku- and Ka-band with new bayonet-style feeds and feed kits for quick RF changes. The terminals have a built-in receiver, are scalable with 75cm, 98cm and 1.35m reflectors, and flexible with modem, BUC and LNB options.

This new, ruggedized, 1.35m FIT platform was developed at the request of several customers looking for high wind auto-acquisition applications. This terminal has a rugged positioner paired with a high-stiffness 6-petal reflector and reinforced tripod. This terminal can be delivered in a compact, IATA-compliant, two case pack-up, and can be assembled by one person in five minutes. The terminal operates manually or with auto-acquire in X, Ku or Ka-band, and is designed to operate in strong winds without additional wind stiffening. It offers a new bayonet-style feed mount, quick-change RF kits, an optional terminal control module with a spectrum display, BUC and LNB options, and RF or modem peaking.

The motorized auto-acquire models operate with the AvL AAQ antenna controller, which has an optional module with a spectrum display. Manually operated terminals point with new manual point computer assisted user interface.

The new 1.2m 1030-T is a new take on an antenna AvL has been producing for many years. This ruggedized terminal operates on a lightweight one-piece tripod that easily unfolds and anchors for a quick set-up. Once the tripod is in place the positioner attaches quickly with hooks and locks, and the positioner includes and I/O panel with connectors.

The offset 1.2m reflector flexible removes from the positioner to enable a compact pack-up as the antenna packs into two IATA-compliant airline checkable cases. This antenna is used by FirstNet civil emergency management agencies at both federal and local levels to support emergency communications.

AvL’s 85cm 830-T FlyAway is a rugged, yet lightweight, antenna designed for rigorous use by military operators. The antenna packs into two, IATA-compliant airline checkable cases and can be assembled by one person in five minutes. The antenna is configurable with multiple modem, BUC and LNB options.

Considering the immense changes and challenges we’ve all faced in 2020, AvL has remained as rugged and reliable as its products. We were excited to continue growing during 2020 and add important team members and capabilities. Our engineers immersed themselves in product development and enabled the launch of many great new antennas. We’re proud to be a member of the DIB — now more than ever —– and a valued supplier to the U.S. Department of Defense.

Though 2020 has been a year of challenges, everyone at AvL is looking forward to 2021 and the return to face-to-face meetings and events, and we’re looking forward to spending time with our valued customers.

AvL’s new product and new technology roadmaps for the next few years include several tactical LEO/MEO tracking terminals, fully electronically steered array antennas and numerous small yet rugged flyaway antennas now going through ARSTRAT certifications.

We don’t expect 2021 to be without challenges, but the AvL team is committed to supplying our customers with much needed and high-quality satellite communications products.

Author Krystal Dredge is the Marketing Director for AvL Technologies