Peter Kant is CEO of Accion Systems. Peter Kant brings two decades of experience at the nexus of business, government, technology and policy including leadership positions in state and federal government, large companies, start- ups, and non-profits. He also currently serves on multiple corporate boards and advisory boards of venture funds. Immediately prior to Accion, Peter was CEO of Synapse Technology, a security AI company that was acquired in 2019.

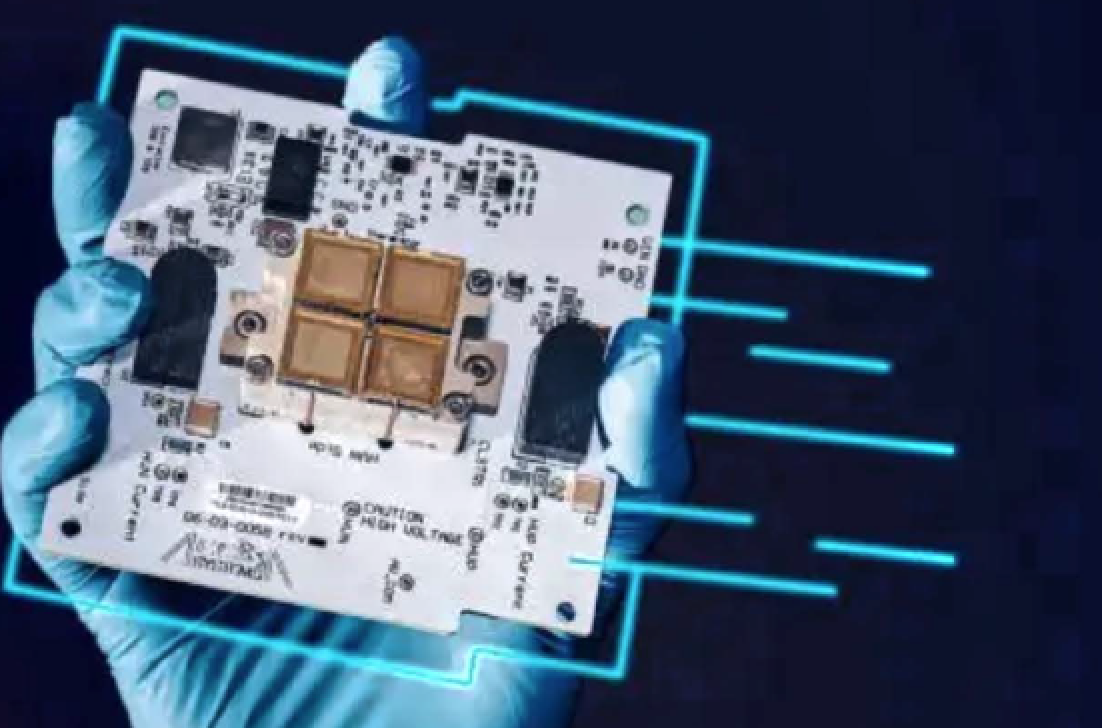

The new ion thruster for New Space: the Tiled Ionic Liquid Electrospray (TILE) Engine.

Peter previously served as Vice President, Federal Partnerships at SRI International where he led SRI’s overall federal government strategy, programs, and relationships. Peter also led SRI’s Center for Innovation Strategy and Policy as Executive Director. The Center focuses on the impacts of science and technology on public policy and building innovation-led economies.

Prior to joining SRI in 2014, Peter served as Executive Vice President at OSI Systems, Inc, a publicly traded security and medical technology firm. Over his 10-year career at OSI, he held multiple positions (primarily at Rapiscan Systems) including, leading the International Division, leading the US Division and he also held senior roles in global government affairs and business development.

Peter started his career in government service working in political positions at the state and federal levels. He worked for Congressman Joseph P. Kennedy II; served as Policy Director for the Texas House of Representatives; and served as an appointee in President Clinton’s administration at the U.S. Department of Agriculture and on Vice President Gore’s Domestic Policy staff.

Peter earned his undergraduate degree in politics and economics from Brandeis University and his Masters of Public Policy at Duke University.

How did you get connected to Accion Systems and why did you think this was an important move for yourself?

Peter Kant

I have Natalya Bailey, one of Accion’s co-founders to thank. She and I met when I was CEO of another company that shared a common VC fund investor. We hit it off, and when I sold that company, Natalya asked if I could help Accion as an advisor given my experience with the U.S. government and with productizing hard tech. I loved what the company was doing, so I joined as an advisor. A few months later, Natalya and the board asked if I would join as CEO to enable Natalya to focus on our tech as CTO.

It was the correct time for me to join. The company is now moving from the really deep R&D phase to selling into the market, refining the product, and scaling up manufacturing. While I’m not a rocket scientist like the two co-founders, taking companies, especially hardware companies, into productization and into scalable sales is what I do.

Space is in an exciting new phase in its development. The question used to be, “can we get something into space?” Then it was, “can we get something into space and keep it there successfully?” And now the next phase of economic development in space is about moving and navigating. With the rapid proliferation of spacecraft, we need propulsion on every spacecraft to keep the industry sustainable and responsible. Accion is one of the few companies, perhaps the only company, that can do that for almost any type of satellite and do it safely. It is very exciting.

How does Accion support the government sector and why is that a great fit?

Peter Kant

Much of Accion’s early work at MIT was with the government, primarily in research and development, working with the Department of Defense, NASA and other space- related federal agencies. As a Boston-based company, everything we do happens in the United States, which is very appealing from a national security perspective.

We’re now moving into supporting actual government missions. One of our propulsion systems is currently on-orbit on a mission mimicking NASA’s MarCo Cubesats, which were the first cubesats to perform an interplanetary mission when they accompanied the InSight lander to Mars. The goal of the mission is to prove that our ion electrospray thruster can more safely provide the same capabilities as the original cold gas thruster with a smaller size, weight and power footprint.

We’re showing that safer, more efficient propulsion technologies can be used by NASA and other government agencies. The Department of Defense and the intelligence community are putting large constellations of satellites in LEO, MEO, GEO and other orbits. Those constellations need precision navigation, precision attitude control, and above all resiliency and safety. They absolutely can’t be explosion risks that endanger other satellites or leave persistent space debris.

As an example, Hall Effect Thrusters, the most common form of electric propulsion systems in use today, are inherently risky in that they use highly pressurized propellant tanks that, if ruptured, would cause a devastating explosion littering the orbital plane with dangerous debris. Their propellants, often Xenon, are also toxic and hazardous.

Our TILE system is so safe it’s qualified to go into the ISS and it’s safe enough to ship with the U.S. Postal Service. It’s not pressurized and has a fault tolerant design, wherein a single failure won’t compromise the ability of the thruster to fire. Another advantage is TILE’s ability to move critical spacecraft out of harm’s way. Anti-satellite weapons are a growing threat that have the potential to cripple America’s space infrastructure. Satellites need to be able to move out of the way at a moment’s notice.

Unlike many propulsion systems that require long warm-up and cool-down periods, TILE can fire almost instantaneously after it receives the signal from the ground. TILE also has no detectable emissions, which enables satellites to adjust their trajectory in stealth. To be clear, most satellites follow a predictable trajectory and can easily be tracked even if they’re not using propulsion. The lack of detectable emissions from the propulsion system makes it possible for satellites to change their orbits without adversaries noticing, keeping missions a secret.

Please give us a 10,000 foot view of TILE and the technological advantages over other systems.

Peter Kant

Today there are more than 3,700 satellites in LEO, and that’s doubling almost on an annual basis. Should any satellites using pressurized gas for propulsion be pierced or have a catastrophic event, it would create a lot of space debris. This space debris can then collide with other spacecraft to create exponentially more space debris in a cascading chain reaction known as the Kessler Syndrome. Imagine 3,700 little bombs flying around in space and extrapolate that to 7,000 next year. Then large constellations may contain as many as 30,000 units. That’s a lot of little bombs flying around in space.

With TILE, the propellant we use is so safe it comes in a plastic tank similar to an inkjet cartridge reducing the risk of space debris. In fact, we can help mitigate space debris by putting propulsion on spacecraft that didn’t have it before and getting them out of the way or out of orbit.

The core of Accion’s TILE systems is a thruster chip about the size of a postage stamp. These chips can be arranged together in various arrays, making it highly scalable. We just add more or fewer of those little chips to meet the amount of total impulse and thrust needed for that spacecraft mission without redesigning a whole new system. The thruster chips can be co-located to maximize thrust, or distributed across the spacecraft for finer attitude control. You can also separate the chips from the propellant tanks and electronics to make space for your other payloads; the configuration is extremely flexible.

Traditional propulsion also requires a lot of fuel and power, meaning you can’t turn on the propulsion and the primary (remote sensing, communication, etc.) payloads at the same time. With TILE, you can. Our next-gen system is poised to be the most efficient propulsion system on the market. This means that companies can do a lot more with a lot less satellite.

What are the more far reaching implications of this technology?

Peter Kant

Payload computers, solar panels, and o t h e r spacecraft components have all become smaller, more efficient and safer. One area that hadn’t seen the same level of innovation is propulsion... until now. If I’m a satellite operator, I used to have to consider three, four or five different types of propulsion technologies. I then had to figure out how to integrate them in my spacecraft. Now there’s one solution that’s plug-and-play and scalable for any spacecraft. And it’s safe. We’re also not asking our customers to redesign their spacecraft to integrate large, bulky propulsion systems, make room for huge tanks, or mitigate potential explosion risks. That’s why we believe TILE will bring reliable propulsion to all spacecraft and make the space environment more mobile, safe, and sustainable.

Where do you see Accion moving toward in the next five years?

Peter Kant

Our major focus is expanding our TILE product line to have a family of scalable thrusters that support larger spacecraft and more complicated maneuvers. We’re continuing to scale up to provide a family of thrusters to do just that.

With our latest round of funding from Tracker Capital, we’ll be able to design and build larger products and scale up our manufacturing significantly. Up until now, each of our TILE systems have been manufactured individually, but there’s a lot of potential for mass manufacturing given our unique MEMS design and use of readily-available, low-cost materials. The semiconductor industry manufactures billions of computer chips each year, and the same microfabrication processes can be used to make our thruster chips. Once we unlock that level of mass production, we’ll be able to make our chips faster, cheaper, and at an even higher level of quality. This will be a game changer for future satellite constellations.

What are the biggest sustainability concerns in space?

Peter Kant

There are two areas Accion is focused on in terms of sustainability: making sure the things that go into space are safe and extending the useful life of satellites and spacecraft. For the first part, all satellites need the ability to avoid collisions, to deorbit at the end of their mission, and of course, to not explode. To do that, we need low cost, reliable, safe and efficient propulsion, and Accion has a huge role in that. We also need to extend the life of valuable space assets. Many current propulsion systems run out of propellant, leaving their spacecraft without the ability to move. We are designing systems that can be refueled to extend the life of spacecraft.

How has TILE changed over the years, both in terms of its capabilities and also the manufacturing process?

Peter Kant

TILE first started on the bench at MIT with Louis and Natalya and the team at the Space Propulsion Lab. They used handmade materials with brass board connectors between the propellant tanks and the chips.

Over the years, Accion has focused on increasing thrust, lifetime, efficiency, and scalability. We have been exponentially increasing TILE thrust and total impulse. Today, with that same amount of surface area and the same small chip size the team made originally, we deliver five times the amount of total impulse and thrust of earlier systems.

We are working under what we call “Moore’s Law of Propulsion.” Much like how increasing the transistor density of computer chips increases their computing power, we can increase the thrust of each chip by increasing the density of ion emitters. So we are able to increase thrust and total impulse by adding thruster chips, and by increasing the thrust of each chip.

As we apply microelectronic manufacturing techniques to our TILE chips, each new model will improve in quality and performance while reducing costs. We’re already starting to see that with the next generation of TILE coming out later this year and the TILE 3s that are in space now, versus what was on the bench just a few years ago.

What are significant milestones that you’d like to highlight as far as showing the company’s advancement?

Peter Kant

We have already achieved a couple of milestones this year. First, we built and delivered TILE systems that were integrated safely on multiple types of commercial satellites, passed all flight qualifications and are operating in space. We are now well underway in developing our next TILE product that is meant for larger spacecraft. We’re really excited about that product launching for commercial customers next year. Stay tuned to SatMagazine for that important announcement.

accion-systems.com