Bob Vampola is the vice president of Microchip Technology’s aerospace and defense business unit. He is responsible for growing the company’s A&D business and works across Microchip’s business units to identify products and solutions for this industry, including the defense, commercial aerospace and space markets. Bob’s team supports the A&D market with product design and test engineering, radiation engineering, application support, product marketing, and business development.

Based in Irvine, California, Bob has more than 30 years of experience in the semiconductor industry supporting aerospace and defense customers and programs. Bob began his career working for Hughes Aircraft as a member of the technical staff where he designed command and control electronics supporting infrared systems used for military applications requiring a secret clearance. From there he took on various positions at Actel supporting the design and implementation of FPGAs in the customer base and driving key business opportunities across the southwestern United States.

After Actel was acquired by Microsemi in 2010, Bob began driving sales of all Microsemi products as a regional sales manager supporting a team of direct sales managers, application engineers, manufacture representatives, and distributors. Under Microsemi, Bob became a Director of A&D Sales focusing specifically on A&D clients and was then promoted to vice president of aerospace and defense where he put together a team to focus on the aerospace and defense markets world-wide. Microsemi was acquired by Microchip in 2018, where Bob continues his A&D focus.

He graduated from University California Santa Barbara in 1987 with a bachelor of science degree in electrical engineering. The new space market is rapidly growing, with both public and private entities exploring Low-Earth Orbit (LEO) missions. To support this emerging market, there is a need for commercial off-the-shelf (COTS) or standard components that can operate in harsh environments.

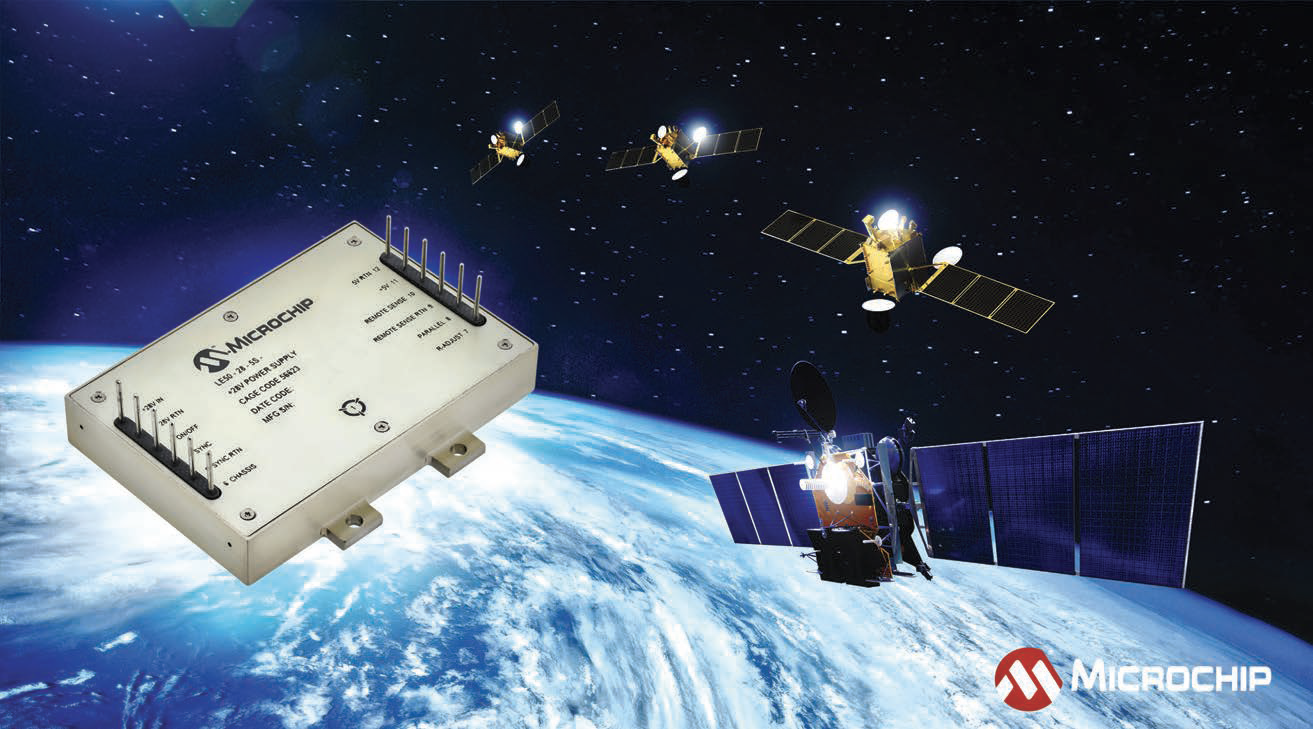

Microchip has more than a 60-year legacy in space enablement with traditional space-grade products. Now, for the next frontier of new space, Microchip is introducing products designed for LEO applications with the standard LE50 power devices that are radiation-tolerant, cost-efficient and provide high-reliability. As Microchip has more 60-years of space heritage from Apollo 11 to Artemis.

Describe the evolution of technology and solutions the company provides to enable space missions.

Bob Vampola

Bob Vampola

We offer one of the industry’s most comprehensive product portfolios for space applications, which includes radiation-hardened and radiation-tolerant products. Our unique, scalable approach allows us to cover a wide range of quality levels with the same product. Customers can choose from a range of packaging materials and qualification options to meet their mission goals.

Microchip’s position in the space sector is also strengthened by a basis of legacy products and solutions that resulted from a number of key acquisitions of companies that design and test high-reliability products used in space. These companies include Millennium Microtek Thailand (MMT), Atmel Aerospace, Microsemi, Vectron, and others. As a result, Microchip’s space legacy dates back to the early stages of space exploration, including contributions to the Voyager and all the way to the current Mars and the recent lunar missions.

Traditional space or deep space missions need rugged and reliable solutions that could last for decades in space with mission time >5 years minimum. Microchip has provided innovative solutions FPGAs, microcontrollers, microprocessors, power and discrete devices, memory

products, communication interfaces and oscillators. With a focus on power management, we supply electromechanical relays and custom power supplies. In our increasingly connected world, a new frontier of exploration known as New Space is spurring a broad range of satellite applications.

Individual satellites can be used for higher resolution imaging as they orbit close Earth; however, we are seeing more companies engaged in forming constellations of large numbers of relatively smaller satellites to form a web or net around the Earth to give uninterrupted coverage. By working in tandem, these constellations provide simultaneous coverage and are used in applications such as internet service and telecommunications.

This alternate approach is an example of what New Space has enabled with the launch of multiple, smaller satellites with lighter payloads for commercial purposes. Satellite internet services are slowly and steadily competing with traditional broadband and are providing more reliable connectivity for remote areas, passenger vehicles and even for aerospace.

What are the main factors to consider when designing for space applications.

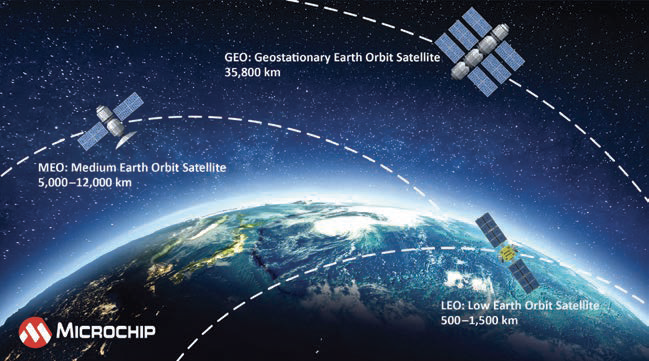

Bob Vampola

The space environment consists of effects such as solar plasma, protons, electrons, galactic cosmic rays and solar flare ions. This harsh environment causes environmental effects such as Displacement Damage (DD), Total Ionizing Dose (TID) and Single Event Effects (SEE) that result in device level effects. GEO orbits have more stringent radiation requirements compared to LEO orbits.

The power converter considerations should be in line with the orbits in which satellite operate, as well as mission time. The volume requirement for LEO tends to be higher, due to number of smaller satellites launched to form the constellations. Satellites power management face stringent requirements of complying with various MIL-standards to withstand the harsh environment. The power supplies used in these satellites also need to minimize size, weight, power and cost.

Microchip provides DC-DC space converters that are suitable for these applications with the standard, radiation-hardened, SA50 series for deep space or traditional space satellites in GEO/MEO orbits and standard radiation-tolerant LE50 series for LEO/New Space applications. Using standard components in non-hybrid structure can prevent Internet of Things (IoT) jeopardy and mission schedules risk to ensure reliable and rugged solutions with faster time to market at the desired cost structure.

Power management and supplies are integral to the success of a mission, what solutions does Microchip offer?

Bob Vampola

The balance between cost effectiveness and reliability is key to enable success in these applications. Microchip selects radiation-tolerant components where needed with high-reliability COTS components to balance cost and reliability for New Space.

We have the unique capability of providing most of the building blocks required for space system architecture including, but not limited to, power converters, LDOs, voltage regulators and point of loads that are used to power FPGAs designed systems, motor controller applications and other systems.

The LEO market is rapidly growing as private and public entities explore New Space, which requires everything from 5G communication and smallsats to IoT applications. There is an increased demand for standard, space-grade solutions that are reliable, cost effective and configurable. The COTS radiation- tolerant LE50-28 series are isolated DC-DC converters with 50W power converters available in nine variants with single- and triple-outputs that range from 3.3V to 28V.

The current market contains either commercial power converters that are not radiation tolerant, which poses a great risk to the satellite mission life, or expensive radiation-hardened power converters. The LE50 fills the gap between these two by offering a cost-effective radiation-tolerant solution for satellite missions.

Unlike other pure commercial offerings, the LE50 series uses radiation-tolerant components where needed for long-performance missions in LEO- radiation environments.

The LE50 series offers cost efficiency, small footprints and configurability for faster time to market. The ability to modify the units using standard components with printed circuit card construction to meet exact power system requirements.

Microchip has the capabilities to make derivatives of standard products as well as full custom solutions to meet the demands of new space applications without compromising lead times. Microchip offers standard products, derivatives and full custom solutions.

What are the key technical specifications of the LE50-28 power converters?

Bob Vampola

LE50-28 power converters are available in nine variants with single and triple outputs for optimal design configurability. The power converters have a companion EMI filter and let you easily design to scale and customize by choosing one to three outputs based on the voltage range needed for the end application.

This series provides flexibility to up to four power converters to reach 200W. The LE50-28 family offers space-grade radiation-tolerance with 50 Krad Total Ionizing Dose (TID) and Single-Event Effects (SEEs) latch-up immunity of 37 MeV·cm2/mg linear energy transfer.

LE50-28 series is based on forward topology that offers higher efficiency and <1% output ripple. The size of LE50 is extremely compact “3.055” x 2.055” x 0.55” with lower weight of just 120 grams.

The LE50-28 is a standard, non-hybrid, space-grade, radiation-tolerant DC-DC power converter that uses surface-mount component construction, giving customer flexibility and customization to fit specific applications and requirements. Complying with the Mil-Std-461, Mil-Std-883 and Mil-Std-202 standards, the LE50-28 family gives the confidence to start with available off-the-shelf technology and quickly scale up development to reduce risk and development time.

Designed to serve 28V bus systems, LE50-28 isolated DC-DC power converters can be integrated with our PolarFire® FPGAs, microcontrollers (MCUs) and LX7720-RT motor control sensors for a complete electrical system solution. This enables customers to use cost effective standard LE50 converters to customize and configure solutions using paralleling, synchronizing features to form more intricate power systems that can meet the demand of LEO Power management.

What other New Space solutions does Microchip offer?

Bob Vampola

Microchip is offering a wide range of scalable solutions targeting New Space applications. Our unique, scalable approach allows us to cover a wide range of quality levels with the same product. Customers can select from a range of packaging materials and qualification options to meet their mission goals.

For New Space’s low- to mid-volume constellations with stringent cost and schedule requirements, sub-QML versions are the optimal solutions that combine the radiation tolerance of QML components with our space flight heritage to enable lower screening requirements for lower cost and shorter lead times. LE50 companions in this category are FPGA RTG4 plastic version and High Performance Spaceflight Computing (HPSC) LEO variant.

Our radiation expertise and space-qualified portfolio extends to a wide range of COTS solutions that target the industrial and automotive markets. Leveraging the large ecosystem and performance of COTS AVR® microcontrollers (MCUs) and Arm® core-based MCUs, we offer scalable solutions that start from COTS to space-qualified, radiation-tolerant and radiation-hardened versions. The LE50 companions in this category are RT PolarFire® SoC FPGA and the RT AVR and Arm-based microcontroller solutions upgraded from automotive solutions.

Microchip’s offering of Rad Tolerant LDOs and Voltage regulators compliments the LE50 DC-DC converter by completing the full power system architecture that powers the Radiation tolerant FRGA’s, such as RTG4 and RT PolarFire® FPGA and radiation tolerant MCUs, such as SAMD21RT and SAMV71RT that driver the final applications such as Altitude determination, communication, command and data handling, thermal control unit , power processing unit to name a few.

For example, MIC69303RT, a Rad-Tolerant LDO, can be used at the output of LE50 to converter for adjustable voltage of range 0.5 V to 5 V to feed the supply need of FGPA or MCUs with excellent regulation. Similarly, for Microchip’s New Space offerings, we provide a range of MOSFETs, Rectifiers and Schottky Diodes qualified for JANS/JANTX standards.

Finally, Microchip offers a comprehensive system solution for space applications with many devices that can be designed around an FPGA, MPU and MCU, including the power and discrete devices, memory products, communications interfaces and oscillators.

www.microchip.com