The economics of space has changed significantly over the past decade. We’ve seen amazing reductions in launch costs that have paved the way for innovative satellite constellations with real world benefits that can be monetized. Applications such as Earth observation, providing world-wide internet and asset tracking can improve our lives in many ways, while generating significant revenue streams.

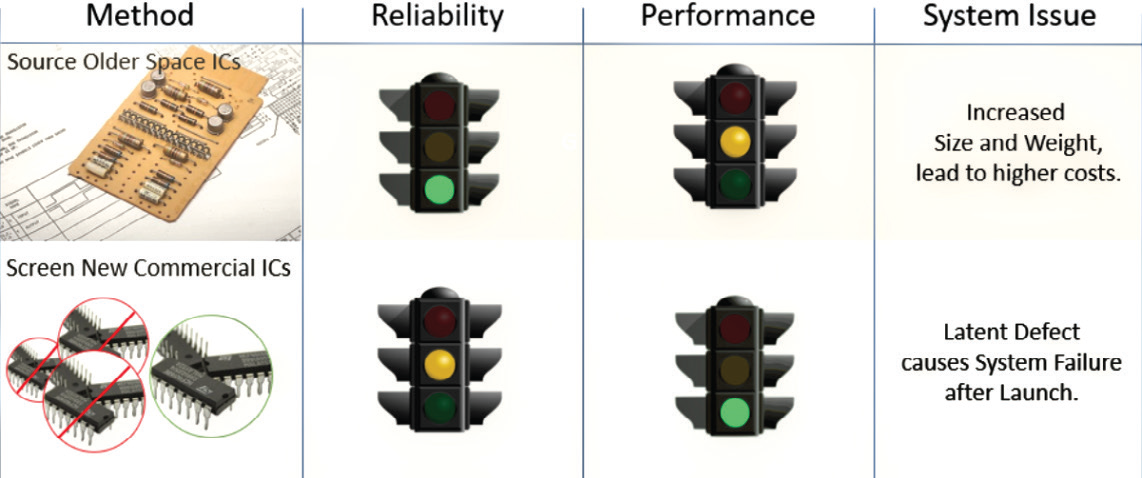

Todays methods of radiation protection

Todays methods of radiation protection

Along with the significant reduction in launch costs over the decade, the standardization of the cube-sat platform has also played a large role in the changing space economy. Now many vendors are developing components for the cube-sat platform that can be easily integrated into functioning and useful satellites, opening the sector to many groups who would have been unable to participate in the past. This new frontier of science advancements promises to unlock technologies we have yet to achieve.

While there is much positive change in the industry, there is one aspect that has not kept up with the fast pace of the rest of the sector: the integrated circuit (IC).

The Integrated Circuit

The importance of the integrated circuit to any modern technology cannot be overstated. Our connected lifestyle, transportation and entertainment are all possible because the ICs have become smaller, faster, and cheaper. The nursery of the IC was the aerospace industry, but over time the devices became commercial commodities, and the industry that raised the IC to prominence, now must pay dearly to obtain even outdated technology that can meet the requirements of space travel.

In the early years of the smallsat industry, many manufacturers were leveraging these commercially available components for their cost advantage and modern technology, taking risks to avoid using expensive and hard to source radiation hardened ICs, in specialized packaging. These space grade devices can meet the environmental requirements, but lag technology state-of-the art by over a decade and can have manufacturing lead times that could be in years.

This risk may be acceptable for short duration, very low earth orbit missions, using redundancy and sheer luck to succeed. The facts are that these components will start to fail once the radiation environment becomes more hostile.

Now that these satellites are being used in on-going business endeavors, they must work, and must achieve a return on investment. Satellite manufacturers differ in their awareness and approach toward the radiation and reliability issues.

Some manufacturers take the “ostrich” approach, they use commercial components, knowingly waiving off any radiation concerns. Others recognize that radiation effects on electronics cannot be ignored and actively seek out radiation tolerant components or “up- screen” commercial components to make sure they work under radiation environments.

The cost of ownership in both cases make the business model uncertain in a best-case scenario and leave the satellite developers in a dilemma. The challenges of the traditional space grade ICs make it almost impossible to close the business cases for proposed constellation and the use of commercial components translates into assured destruction of some of the units, but how many and how often?

There are manufacturers also taking a “middle of the road” approach. They utilize commercial components and balance those devices with radiation tolerant components to ensure that no radiation effects have corrupted the functionality of the circuit.

An example of this approach is to use a radiation tolerant voter device to ensure that a flipped bit in a memory does not turn on a device when it should not be on, but the cost and sourcing of such a device is still an agonizing process.

If we truly want to unlock the potential of the space economy, we must solve the rad-hard IC problem.

Solving The IC Problem

As with all growing sectors, when there is a problem, firms will use their innovation and ideation to create solutions. Implementing a patented semiconductor process, in the manufacture of common components, has caused a disruptive evolution in the radiation hardened semiconductor marketplace.

In the above voter scenario, there is now a solution, Apogee Semiconductor’s AP54RHC301 logic voter. The decision makers in all scenarios now have a new option in their solutions tool kit. Implementing a rad hard process in commercial semiconductor foundries, using standard plastic packaging, and proven commercial production flows, Apogee Semiconductor has been able to greatly improve the radiation performance of standard silicon devices to meet the needs of space travel, but also reduce the cost of radiation hardened components to enable satellite manufacturers to close on their business case, without the risks of commercial components.

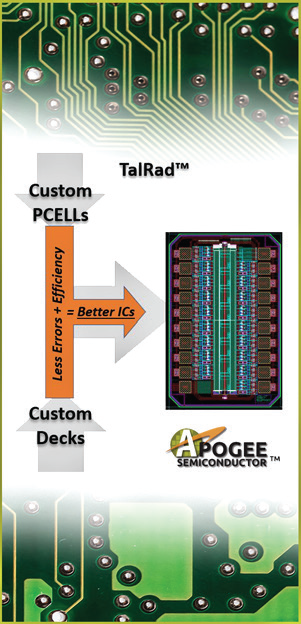

Apogee Semiconductor first partnered with TSI Semiconductors, a silicon foundry from Roseville, CA, to develop a radiation hardened process delivery kit (PDK) that integrates into TSI’s 180nm commercial high voltage process. With only minor changes introduced to a commercial process, it is possible to reduce impacts on cost while keeping the reliability high. Apogee Semiconductor’s TalRad™ process accomplishes this while improving the radiation performance by over ten times compared to the commercial components.

Unlike the protype, test, protype, test…iterations typically seen in hardware, this is not possible with silicon. Silicon mask sets can cost millions of dollars and fabrication cycle time can be 2-4 month. This makes the iterative engineering approach not practical for IC design. Instead, IC designers rely on CAD tools and run constant simulations to verify and iterate their designs. Without integration of rad-hard components into these tools, the cost and time required for a rad-hard design can be over three times what is seen commercially. The TalRad™ kit seamlessly integrates the rad-hard components into these tools and solves the design cost and time-to-market problem with developing rad-hard ICs.

What About Packaging + Test?

Making rad-hard design more efficient solves a big part of the problem but we also need to address the cost of assembly and test. Traditionally, space ICs are packaged in expensive hermetic packages that are large and reduce the performance of the IC. The space industry has started to accept plastic packages and New Space customers are using them almost exclusively. There are ongoing efforts to develop standards for traditional space customers to fly plastic ICs, which is a step in the right direction.

While standardization is a positive step, the industry does have to be careful to avoid unnecessary screening costs that do not measurably improve reliability. Testing and screening cost can be over 80% of the cost-of-goods-sold of space ICs. Care must be taken to achieve the optimal balance of reliability and cost. From its beginnings, Apogee Semiconductor has focused on releasing space products in plastic packages with optimized test flows optimized for large constellations.

Anton Quiroz

Malfunctioning satellites can cause orbital debris if they crash or become “zombie” satellites causing interference as they blast the Earth with unwanted radio signals. Continuing to use non-rad hard commercial-off-the-shelf ICs is a reliability risk the industry needs be concerned about.

apogeesemi.com

Author Anton Quiroz is the Chief Executive Officer of Apogee Semiconductor. Apogee Semiconductor’s mission is to change the economics of space by bridging the gap between rad tolerant and commercial ICs to enable mega- constellations. We need more of these amazing constellations to be able to constellations. We need more of t close their business cases, reliably.