Propulsion systems enable satellites to maneuver while in orbit and are important for a host of capabilities—from station- keeping to formation flying to specialized missions. Scaling down propulsion devices from large satellites to small satellites has proven to be challenging due to volume and power constraints as well as unique smallsat requirements, such as “do no harm” when flying as a secondary payload. Therefore, to incorporate a propulsion system on a smallsat necessitates tradeoffs between subsystem performance, footprint, and power.

As the industry grows, more missions require propulsion, and new systems must be envisioned, developed, tested, and flight-proven. The Aerospace Corporation (Aerospace) is deeply invested in all areas of this lifecycle.

Dr. Hsu and Dr. Rhodes at work in the HyPer thrust chamber.

Dr. Hsu and Dr. Rhodes at work in the HyPer thrust chamber.

On the prototyping side, Aerospace has worked on several small satellite propulsion systems, including cold gas, steam, electrolysis, and monopropellants. One such device is HyPer, a green hydrogen peroxide (H2O2) propulsion system with a unique patent-pending design. In the thruster, reactive H2O2 vapor is vacuum-evaporated from the surface of the stored liquid.

HyPer: prototype and conceptual schematic.

The vapor then flows to a catalyst bed that rapidly decomposes the hydrogen peroxide. The resulting exhaust gases produce thrust, propelling the spacecraft forward.

HyPer: Prototype and Conceptual Schematic

HyPer provides millinewtons of thrust with several notable advantages over other small satellite propulsion systems. Because hydrogen peroxide is a green propellant (compared to traditional chemical propellants, like hydrazine, which are toxic), and tank pressure is low, safety concerns are minimized.

Power requirements are also low, which makes it well-suited to even the smallest satellites. In addition, a vapor system utilizes all the liquid propellant (i.e., none stays trapped in the system), and the performance remains constant and can even potentially improve over the life of the thruster due to vacuum distillation.

Additionally, many of the hydrodynamic complications (e.g., droplet and bubble formation and thermocapillary flows) that prevent full decomposition in low thrust liquid systems do not occur in a vapor-phase propulsion system.

Dr. Rhodes setting up HyPer in Snake Pit, The Aerospace Corporation’s

micro-p[propulsion ground vacuum facility.

Over the past two years, this concept has transitioned from an idea to a lab-scale prototype to a smallsat-compatible system, including flight software and electronics. Much of this effort was built off of the vast knowledge developed and refined on the AeroCube platform. Aerospace has been designing and launching CubeSats since 1999. Additional support was provided by the Combustion Physics Lab at the University of Southern California.

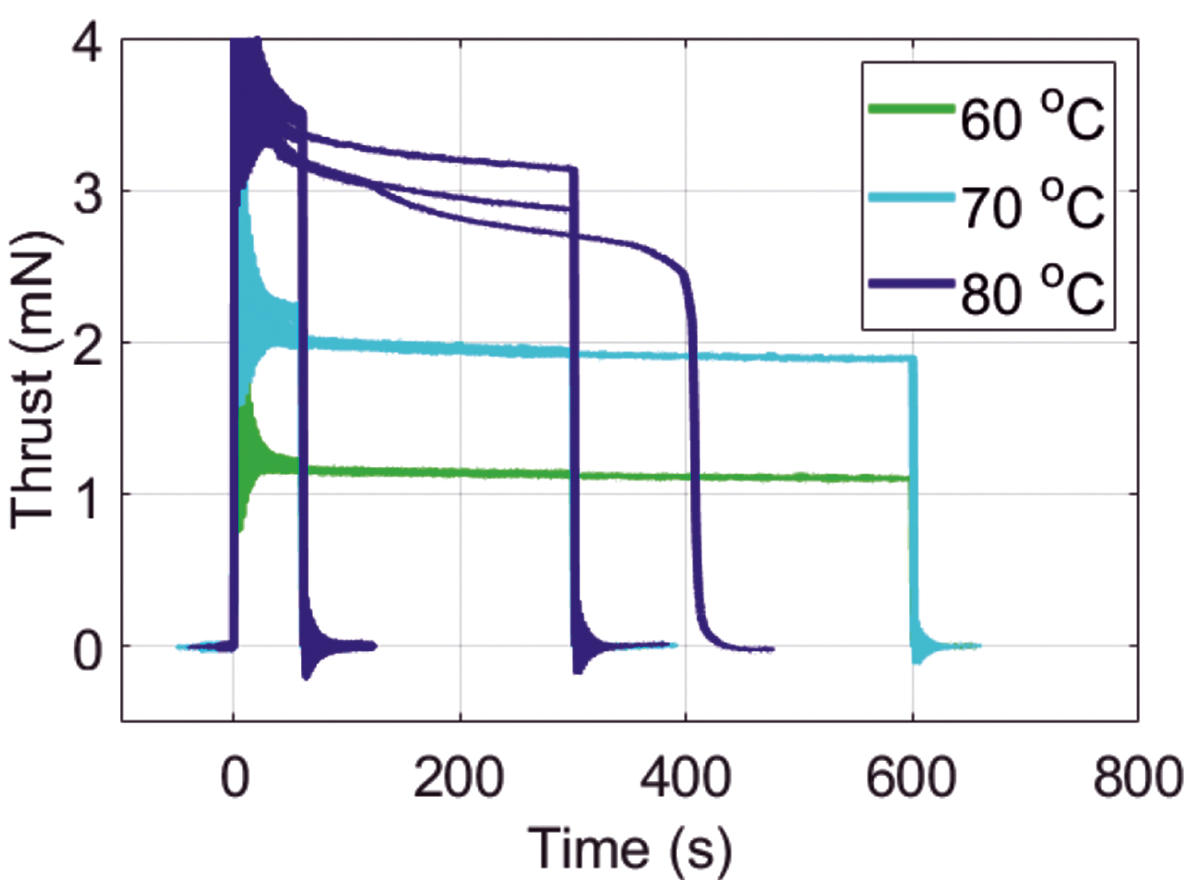

An important step in any propulsion system development is verification of and iteration on performance. HyPer has an ideal theoretical specific impulse (Isp) of >220 s with an adjustable thrust range in the millinewtons based on the set tank temperature.

However, due to the miniaturization of the system and the low propellant flow, heat transfer and boundary conditions in the system will dramatically affect performance. While some of these can be captured with pressure and temperature sensor data, the full picture is not presented and an artificially high performance can result.

Direct thrust measurements during the design phase are critical for developing a functional, high-performing system with accurate specifications.

Dr. Rhodes (right) and Madison Piechowski assemble HyPer.

Dr. Rhodes (right) and Madison Piechowski assemble HyPer.

This is another area where Aerospace has stepped up for smallsat propulsion system developers by building a premier micro-propulsion ground vacuum testing facility. Nicknamed “Snake Pit,” the facility possesses instruments specially tailored toward testing miniature propulsion systems.

Snake Pit’s precision thrust stand accurately measures how much force the thruster produces, a capability that many smallsat propulsion developers do not possess. The torsional pendulum thrust stand can measure forces on the order of a few micronewtons (the force of an eyelash falling on a hand) up to tens of millinewtons. This requires extremely sensitive sensors and frequent calibration.

Testing of HyPer in the Snake Pit facility helped inform and drive revisions to the design, specifically in the nozzle. Higher set tank temperatures, which correspond to higher propellant flow rates and higher thrust, showed evidence of leaks at the nozzle interface. Lower than predicted thrust levels and mass flow rates revealed important boundary layer conditions. These areas were then targeted in the next iteration. Beyond HyPer, many smallsat commercial, university, and government R&D thrusters have been tested in the Snake

Pit facility.

Thrust measurements from the first test of HyPer in the Snake Pit.

Aerospace engineers and scientists anticipate that small satellites are going to become increasingly capable. As access to space becomes more readily available and inexpensive, the demand for small satellite propulsion testing will continue to increase and Aerospace will be ready to support.

All article imagery is courtesy of The Aerospace Corporation

Dr. Brandie Rhodes is an engineering specialist in The Aerospace Corporation’s Innovation Lab (iLab). She is responsible for planning and executing special projects aimed at game-changing innovations and supporting the transition of Aerospace technical products into operational use. She also is the principal investigator for HyPer, a novel small satellite propulsion system conceived and prototyped at Aerospace.

Prior to her current role, Dr. Rhodes worked in the Propulsion Department where she supported satellite and launch vehicle development, launch, and sustainment. This included propulsion system concept design, fluid flow and performance analysis, failure investigation, flight and ground operations, and data review. Dr. Rhodes received her bachelor’s degree in aerospace engineering from the University of Kansas, her master’s degree in mechanical engineering from Stanford University, and her Ph.D. in astronautical engineering from the University of Southern California.

Dr. Andrea Hsu is a senior scientist in the Propulsion Science Department at The Aerospace Corporation. Her primary roles include leading research and development projects and serving as a subject matter expert in small satellite propulsion. Her laboratory research in this area includes managing the Snake Pit vacuum chamber facility, which contains two sensitive thrust stands for experimentally measuring performance of small satellite propulsion systems. This facility has been utilized for collaborative efforts with universities, commercial companies, and government customers.

Prior to joining Aerospace, Hsu worked as a post-doctoral researcher for Sandia National Labs in the area of advanced laser diagnostics applied toward combustion flow fields. She has a background in physical chemistry, spectroscopy, and non-equilibrium hypersonic flow fields, and previously worked as a chemical process engineer for Celanese Chemicals.

Dr. Hsu received her bachelor’s degree in chemical engineering from the University of Texas, and her Ph.D. in chemistry from Texas A&M University.