Kymeta + OneWeb Sign A JDA For A Flat Panel User Terminal

Kymeta and OneWeb have entered a joint development agreement (JDA) to develop an innovative, flat panel, electronically steered, user terminal that is compatible with the OneWeb network to support land fixed applications and leading the way to various mobility applications such as land mobile, maritime, and other mobility needs of the future.

The Kymeta™ u8 flat panel antenna technology provides an innovative solution to interoperate with the OneWeb LEO satellite constellation that supports Communication on the Pause (COTP) and future Communications on the Move (COTM) for military, government, first responder, maritime, enterprise and other commercial customers. The Kymeta u8 based terminal will provide the benefits of interoperability between GEO and OneWeb LEO services to strengthen the reach of the terminal solutions. Under the new JDA, engineering teams from both OneWeb and Kymeta will collaborate to ensure the terminal meets the technical specifications required for compatibility with the OneWeb network.

The announcement comes just months after Kymeta and OneWeb previously collaborated on a pilot program to successfully test and demonstrate a LEO-GEO capable land flat panel user terminal in Toulouse, France, which generated a great deal of interest from customers. The two companies aim to launch their new solution into the market for purchase by the third quarter of 2022.

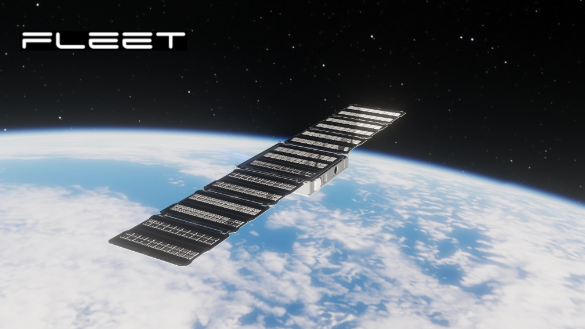

Constellation Of World’s First Fully 3D Printed Smallsats To Be Developed + Launched By Fleet Space

Fleet Space Technologies has announced their future strategy, led by the development of a new constellation of 3D-printed smallsats named Alpha, with the first satellites ready for launch in 12 months. This constellation will reside alongside the existing Centauri constellation. Fleet Space will be able to expand its coverage reach and provide down to sub-second latency, providing an extremely cost-effective means to unlock unprecedented connectivity more quickly and in more locations, however remote.

The Alpha constellation represents a fundamental shift for Fleet Space. Empowered by a recent $26.4 million Series B investment, the startup has expanded the scope of its dedicated R&D arm to create the Alpha smallsat. The creation of the world’s first entirely 3D printed satellite, integrates Fleet’s advanced beamforming technology and patented antennas.

The existing Centauri constellation is among the world’s most advanced space communications systems. Like Alpha, Fleet Space’s latest Centauri 4 smallsat, developed in collaboration with Tyvak, has been integrated with Fleet Space’s breakthrough, smallsat digital beamforming technology that uses an array of multiple 3D printed, all-metal antennas, along with cutting edge Digital Signal Processing.

This beamforming technology provides a substantial increase in throughput of customer IoT data and can service a higher number of customer terminals at once. It does this by generating a high number of highly-directional, low-interfering beams in point-to-point satellite communications. This achieves a high spectral efficiency that improves quality of service through enhanced frequency re-use, faster data rates and more link robustness. Integrating this digital beamforming into a LEO smallsat, not much larger than a half a square meter, is a world first.

Fleet Space team photo.

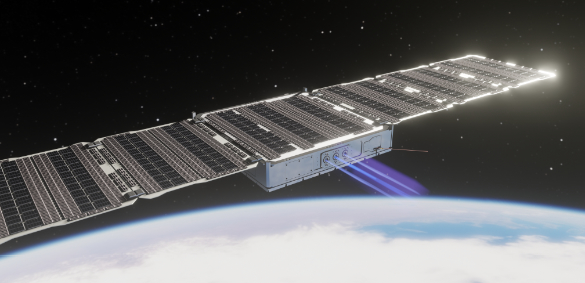

Fleet has a clear track record in advanced manufacturing methods, such as 3D printing. This includes a world-first in metal ,3D-printing patch antennas for smallsats. This proves the company’s approach and the robustness of the technology for much wider use. Indeed, Alpha satellites will have up to 64 of these antennas on board, versus only 4 in the Centauri 4. This represents a 16-fold increase in performance while being only four times heavier.

Fleet Space will ensure the continuity of the Centauri constellation in collaboration with Tyvak International and the launch will occur by the close of 2022. This will ensure service continuity and an increased level of service for all Fleet customers, creating a complimentary constellation that further increases its connectivity speed and reach.

The additional scope of Fleet Space Technologies will arrive at a key moment in the satellite communications industry. Built and deployed over the last 50 years, this market is expected to double in the next seven years, driven by less expensive access to orbit and a combination of new technologies. Matched with predictions by The International Data Corporation that there will be more than 14 billion connected devices by 2025, the demand for global coverage of high speed, low latency connectivity will become unprecedented.

The deployment of Fleet Space’s smallsat Alpha constellation will service this crucial sector by providing limitless connectivity and will add data driven applications. Working alongside its existing smallsat Centauri constellation, it will unlock new markets with continuous coverage, a high data rate of up to 520 kbps and tailored frequency bands servicing current and future generations of IoT devices.

The pace and depth of Fleet Space’s advancements is a clear demonstration of Australia’s position as a global center of excellence for space technology. Supported by the Australian federal government ambition’s to grow the size of the Australian space economy to $12 billion by 2030 and create an additional 20,000 jobs in the field, Australia already boasts launch facilities, commercial rocket launches and a burgeoning space-centric software industry, positioning the nation as a capable, strategic and globally- engaged leader in the field.

Alongside Fleet Space’s advanced smallsats, homegrown Australian technology is also supporting the wider space industry. Fleet Space is leading the Seven Sisters’ Australian space industry consortium in support of NASA’s Artemis program to land the first woman and next man on the Moon by 2024 and create a sustainable human presence for later crewed Martian exploration. Commencing in 2023, the Seven Sisters missions are designed to find accessible water and other resources on the Moon and Mars.

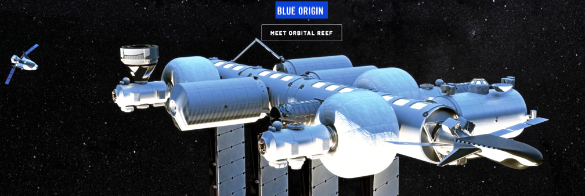

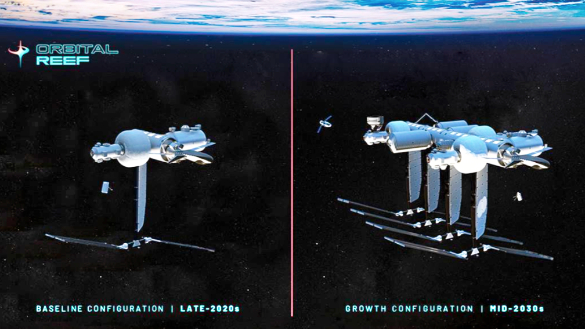

NASA’s Space Station Replacement Development Engages Orbital Reef, Blue Origin, Sierra Space, Boeing, Redwire Space, Genesis Engineering + Arizona State Univ.

Orbital Reef, led by partners Blue Origin and Sierra Space, has been selected by NASA for a funded Space Act Agreement for collaboration to design a commercially owned and operated space station in LEO.

NASA’s Commercial LEO Development program aims to shift NASA’s research and exploration activities in LEO to commercial space stations, helping stimulate a growing space economy before the International Space Station is retired. The Orbital Reef team includes Boeing, Redwire Space, Genesis Engineering Solutions, and Arizona State University.

The industry team brings together all the expertise to develop, integrate, and operate Orbital Reef’s transportation and destination systems and services:

• Blue Origin leads development of the station’s infrastructure, large-diameter metal modules, last-mile space tug, and reusable heavy-lift New Glenn launch system.

• Sierra Space leads development of the LIFE (Large Integrated Flexible Environment) and small-diameter metal node modules, and Dream Chaser spaceplane for crew and cargo transportation with runway landing anywhere in the world.

• Boeing leads development of the station’s operations and maintenance and science module, and Starliner crew capsule.

• Redwire Space leads microgravity research payload development and operations, large deployable structures, and the Orbital Reef digital twin.

• Genesis Engineering Solutions develops the Single Person Spacecraft for routine operations and tourist excursions.

• Arizona State University leads the University Advisory Group, a global consortium of universities for research advisory services and public outreach. Orbital Reef’s vision is to provide an “address in orbit” for anyone.

Early customers may include NASA, its traditional ISS partners and non- traditional governments and agencies needing easier access to space. The station will grow as markets grow, including commercial industries such as research and manufacturing, media and entertainment, sports and gaming, and adventure travel and tourism. and adventure travel and tourism.

A Rocket Lab Reveal: The Neutron Rocket + The Hungry Hippo

Rocket Lab USA, Inc. (Nasdaq: RKLB) has revealed new details about their next generation Neutron launch vehicle.

The well-produced Rocket Lab Neutron video with

Peter Beck is available for viewing at this direct link…

This advanced, 8-ton, payload class Neutron launch vehicle is designed to transform space access by delivering reliable and cost-effective launch services for satellite mega-constellations, deep space missions and human spaceflight. During a live streamed Neutron update, Rocket Lab founder and CEO Peter Beck revealed new details about Neutron’s unique design, materials, propulsion, and reusability architecture for the first time.

Neutron will be the world’s first carbon composite large launch vehicle. Rocket Lab pioneered the use of carbon composite for orbital rockets with the Electron rocket, which has been delivering frequent and reliable access to space for government and commercial smallsats since 2018. Neutron’s structure will be comprised of a new, specially formulated carbon composite material that is lightweight, strong and can withstand the immense heat and forces of launch and re-entry again and again to enable frequent re- flight of the first stage. To enable rapid manufacturability, Neutron’s carbon composite structure will be made using an automated fiber placement system which can build meters of carbon rocket shell in minutes.

Reusability is key to enabling frequent and affordable launch, so the ability to launch, land and lift-off again has been built into every aspect of Neutron’s design from day one. It starts with Neutron’s unique shape, a tapered rocket with a wide base to provide a robust, stable base for landing, eliminating the need for complex mechanisms and landing legs. This balanced structure also removes the need for bulky launch site infrastructure, including strongbacks and launch towers. Neutron will, instead, stand securely on its own legs for lift-off. After reaching space and deploying Neutron’s second stage, the first stage will return to Earth for a propulsive landing at the launch site, eliminating the high costs associated with ocean-based landing platforms and operations.

Neutron will be powered by an entirely new rocket engine, Archimedes. Designed and manufactured in-house by Rocket Lab, Archimedes is a reusable liquid oxygen / methane gas generator cycle engine capable of 1 meganewton thrust and 320 seconds of ISP. Seven Archimedes engines will propel Neutron’s first stage, with a single vacuum optimized Archimedes engine on the second stage. Neutron’s lightweight carbon composite structure means Archimedes does not need the immense performance and complexity typically associated with larger rockets and their propulsion systems. By developing a simple engine with modest performance requirements, the timeline for development and testing can be drastically accelerated.

Artistic rendition of the Neutron rocket landing

on its own legs.

What makes Neutron’s design especially unique is the captive ‘Hungry Hippo’ fairing design. This innovative design will see the fairing form part of the first stage structure and remain fixed to the stage. Rather than separating from the stage and falling away to the ocean like traditional fairings, Neutron’s Hungry Hippo fairing jaws will open wide to release the second stage and payload, before closing again ready to return to Earth with the first stage. What lands back on the launch pad is a compete first stage with fairings attached, ready for a new second stage to be integrated and launched. This advanced design can speed up launch frequency, eliminates the high cost, low reliability method of capturing fairings at sea, and enables the second stage to be lightweight and nimble.

Thanks to Neutron’s ‘Hungry Hippo’ fairing design, the entire second stage will be completely enveloped within the Neutron’s first stage structure and fairing during launch. Thanks to this, Neutron’s second stage is designed to be the lightest in history to enable high performance for complex satellite deployments. Typically, a second stage forms part of the launch vehicle’s exterior structure and needs to provide strength to the vehicle from lift-off, exposing it to the harsh environments of the lower atmosphere during launch. Artistic rendition of the Hungry Hippo releasing the payload to orbit.

Artistic rendition of Neutron’s fairing

opening to expel payload to orbit.

By being housed inside the first stage and ‘Hungry Hippo’ fairing, the requirement for the second stage to withstand the launch environment is eliminated and the second stage can be made significantly lighter enabling higher performance in space. Designed as an expendable upper stage for now, Neutron’s second stage is a six-meter-long carbon composite structure with a single vacuum optimized Archimedes engine.

Rocket Lab is currently working through a competitive process to select launch site, rocket production facility and Archimedes engine test facility on the U.S. East Coast. Rocket Lab expects to create around 250 new jobs to support the Neutron program with many roles open for application now.

Artistic rendition of Rocket Lab’s

Archimedes rocket engine.

“Neutron is not a conventional rocket. It’s a new breed of launch vehicle with reliability, reusability and cost reduction is hard baked into the advanced design from day one. Neutron incorporates the best innovations of the past and marries them with cutting edge technology and materials to deliver a rocket for the future,” said Mr. Beck. “More than 80% of the satellites to be launched in the next decade are expected to be constellations, which have unique deployment needs that Neutron is the first vehicle to address specifically. Like we did with Electron, rather than starting with a traditional rocket design, we focused on our customers’ needs and worked back from there. The result is a rocket that is right-sized for market demand and can launch fast, frequently and affordably.”

Note: All imagery is courtesy of Rocket Lab. Orbital Insight Integrates with Esri’s ArcGIS Platform To Streamline Satellite + Sensor Imagery Analysis.

Orbital Insight Integrates with Esri’s ArcGIS Platform To Streamline Satellite + Sensor Imagery Analysis

Orbital Insight‘s fusion of multi-sensor geospatial data and state- of-the-art algorithms has been helping customers address critical concerns for years—from determining the flow of container ship traffic amid unprecedented supply chain delays to visualizing dynamic intelligence and defense-related threats and anomalies across the globe. With the adoption of Esri’s ArcGIS Platform, Orbital Insight is making it easier for its users to integrate with ArcGIS and analyze their data.

Customers of Esri who also use Orbital Insight GO can now seamlessly work between both systems, making it easier to meet spatial challenges with Esri basemap visualizations directly within the Orbital Insight GO platform and export their analysis to ArcGIS.

The integration with Esri’s ArcGIS Platform provides an integral reference point for analysts as well as a more cohesive and natural user experience. More collaboration is planned, including eventually incorporating Esri’s geocoding technology into Orbital Insight GO.

Orbital Insight, founded in 2013, uses artificial intelligence (AI) to synthesize multiple sources of geospatial data—including satellite images, mobile location, connected cars, and Internet of Things (IoT) devices—into a unified platform that can identify objects; detect anomalies; and observe changes in land use, infrastructure, and human activities across the globe.

Orbital Insight executives recently demonstrated the new streamlined user experience at the US Geospatial Intelligence Foundation‘s annual GEOINT Symposium for industry professionals, showing the ease of importing and exporting data between Orbital Insight GO and ArcGIS.

GO is currently being deployed in top security military networks that have long used Esri software. Companies across commercial sectors, particularly real estate, financial services, mining, and consumer packaged goods, are also using GO to monitor changes globally. The increasing customer overlap between the two companies was a primary driver for Orbital Insight to adopt ArcGIS Platform.

“We are proud to share with Orbital Insight the common goal of helping people make important decisions on a worldwide scale by taking a geographic approach,” said Jack Dangermond, Esri founder and president. “It only makes sense to make that process easier so our users can focus on what they do best.”

“Making that seamless was a really big hit,” said Jens Tellefsen, senior vice president of product and design for Orbital Insight. “We serve similar and overlapping sets of end users, and our analysis is often combined and visualized in the ArcGIS system. With our partnership, we have added ArcGIS basemaps in our application to provide a consistent user experience between Orbital Insight GO and ArcGIS. With our native ArcGIS data support, users can now easily add our analysis directly into ArcGIS with a few simple clicks, resulting in significant productivity improvement for geospatial analysts.”

Orbex Prime Rocket To Use BioLPG Ultra-Low Carbon Fuel

Orbex and Calor have entered into an agreement that will see the UK gas company supply the ultra-low carbon fuel that will launch the Orbex Prime rocket.

Under the terms of the new deal, Calor will supply Orbex with its BioLPG solution, a clean-burning propane produced from renewable feedstocks such as plant and vegetable waste material. This reduces CO2 emissions by as much as 80% when compared to sourcing conventional, liquefied petroleum gas (LPG) from fossil sources.

Calor will also install BioLPG tanks and related infrastructure at the Orbex Launchpad Test Platform (LTP) facility currently being constructed at a dedicated test site close to the Orbex headquarters in Forres, Scotland. The test site is expected to be fully operational by early 2022, paving the way for Orbex to launch Prime from Spaceport Sutherland in the North of Scotland later in the year.

The use of Calor’s BioLPG instead of conventional rocket fuels such as refined fossil kerosene products such as Rocket Propellent-1 (RP-1) is a key element in Orbex’s mission to make Prime the world’s most environmentally friendly space rocket. A recent study by the University of Exeter found that a single Orbex Prime launch would produce up to 96 % lower emissions than a similar-sized launch vehicle powered by fossil fuels – the result of almost entirely eliminating black carbon emissions.

Chris Larmour, CEO of Orbex, said, “Environmental sustainability is built into the heart of Prime and we are proud to be the first commercial orbital space launch company to use a renewable, carbon-friendly fuel. The partnership with Calor – one of the UK’s most well-known brands – to use its BioLPG solution is an important step on our mission to develop a fully sustainable solution that avoids the massive carbon emissions profiles of old-fashioned fossil fuelled launches still being deployed by many rocket companies today.”

Alastair Lovell, Head of Sustainable Fuels at Calor, said, “Calor is delighted to partner with Orbex in such an exciting project as orbital space launch. Orbex is clearly leading the industry with sustainable solutions in the same way that Calor is leading the way in providing low carbon energy solutions for off-grid customers. This partnership demonstrates our shared values of reducing carbon emissions and we are proud to be able to supply BioLPG to achieve this goal.”

Orbex is a UK-based spaceflight company with headquarters, production and testing facilities in Scotland, and design and testing facilities in Denmark. Orbex staff members have professional backgrounds with NASA, ESA, Ariane and several commercial spaceflight organizations. The company is now funded by two of the UK’s largest and most active venture capital funds, BGF and Octopus Ventures, who join two of Europe’s largest venture capital funds, Heartcore Capital and the High-Tech Gründerfonds, as well as strategic investor Elecnor, parent company of Deimos Space, the UK Space Agency (UKSA), the European Space Agency (ESA) and the European Commission Horizon 2020 program.

Comtech Telecommunications Corp. Awarded Million$ Follow-On SSPA Order

During the company’s first quarter of fiscal 2022, Comtech Telecommunications Corp. (NASDAQ: CMTL) was awarded a followon order valued at $1.2 million for their Ka-Band Solid-State Power Amplifiers (SSPAs) that use state-of-the-art Gallium Nitride (GaN) technology for an In-Flight Connectivity (IFC) application.

Comtech’s Falcon 50Ka GaN amplifiers feature a tri-band Block Upconverter (BUC) and are packaged in ARINC 791 compliant housings. Comtech’s Falcon product line encompasses Ku- and Ka-bands and offers high linear power with excellent gain flatness and phase noise performance to support the latest waveform technologies and networks.

The Ka-band Falcons implement multi-sub-band switching, gain adjustment and equalization and cooperative system calibration support, such as Open BMIP (Bitmap Image file).

“Comtech offers a portfolio of GaN-based products that utilize the latest GaN technology to deliver RF amplification enabling high-speed satellite communications from ground based and airborne terminals,” said Fred Kornberg, Chairman of the Board and Chief Executive Officer of Comtech Telecommunications Corp. “We continue to expand in the SSPA market offering both Ku-Band and Ka-Band products for IFC applications.”

Comtech manufactures a wide variety of tube-based and solid-state power amplifiers for military and commercial satellite uplink applications. The Comtech Xicom product range encompasses power levels from 8 W to 3 kW, with frequency coverage in sub-bands within the 2 GHz to 52 GHz spectrum. Amplifiers are available for fixed and ground-based, shipboard and airborne mobile applications.

www.comtechtel.com