Two broad trends in SATCOM uplinks are driving the need for liquid cooled SATCOM amplifiers: the amplifiers keep getting more powerful to support higher data rates, and higher frequency bands being used to take advantage of greater available spectrum.

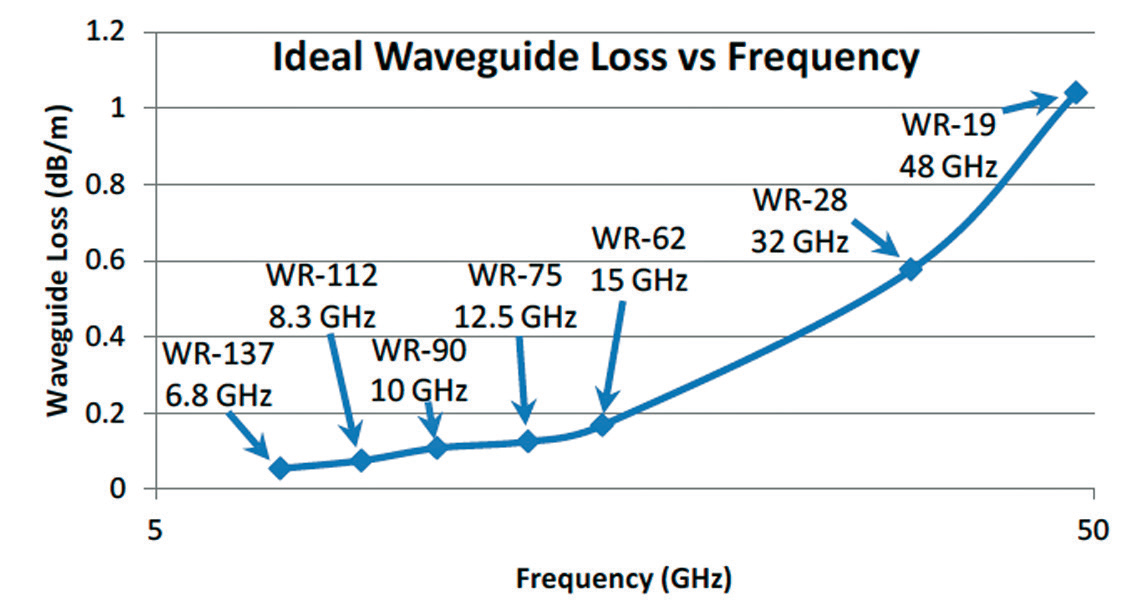

Figure 1. Higher frequency bands drive the need for HPA placement close to the feed.

Higher frequencies mean more loss incurred in the waveguide run and components between the output of the HPA and the feed input (Figure 1). Placing the amplifier closer to the feed enables you to buy less power or use more of the power you’ve bought.

With higher power needed for increasing data rates, you don’t want to waste RF power in long waveguide runs, and your HPAs may generate more heat than before, making it more challenging to cool them up close to the antenna feed.

The Liquid-Cooled Solution

Many current teleport or gateway uplinks are implementing antennas with outdoor TWTAs placed in hubs on the back of the antenna to keep the waveguide runs short. The resulting challenge of cooling the interior of the hub is significant, requiring large air conditioners that require frequent maintenance and are often are the least reliable component of the terminal.

New liquid cooling, as implemented in certain high power SATCOM uplink amplifiers, simplifies design and eliminates operational problems for hub-mount systems:

• No air conditioner in the hub—the number one maintenance and reliability problem

• No air flow requirements or ducting for HPAs in hub – simplifies layout, creates space, allows HPA placement closer to feed

• Eliminate most hub maintenance—no HPA fins or fan filters to clean or replace, no HPA fan failures, no air conditioner regular maintenance

• No HPA noise at the hub —remote the radiator or cooling element to a location with better environment and easier access and keep the neighbors (and the techs) happy

• No variation with temperature—closed loop flow control provides constant baseplate temp even in extreme environments, reducing gain variation and extending life

Other terminals use indoor HPAs, such as Klystron amplifiers, because they want to control the environment for the amplifiers to extend their life, or because they are near residential areas and cannot have the noise of the fans and air conditioning equipment running 24/7.

These implementations spend a lot of energy and money on air conditioning the indoor environment, along with the building and rack space for this RF equipment. Not to mention the power wasted in long waveguide runs. Liquid-cooled HPAs can:

• Dramatically reduce thermal load on general air conditioning system—frees up air conditioning for other uses including expansion of baseband equipment

• Create the option to move HPAs outdoors even in urban or extreme environments with quiet, sealed units, no fins/fans to clean/maintain and no temp variation on HPAs

• Significantly reduce power consumption and thermal dissipation vs Klystrons with liquid-cooled indoor or outdoor TWTAs that draw much less power at lower output RF power

The Workings

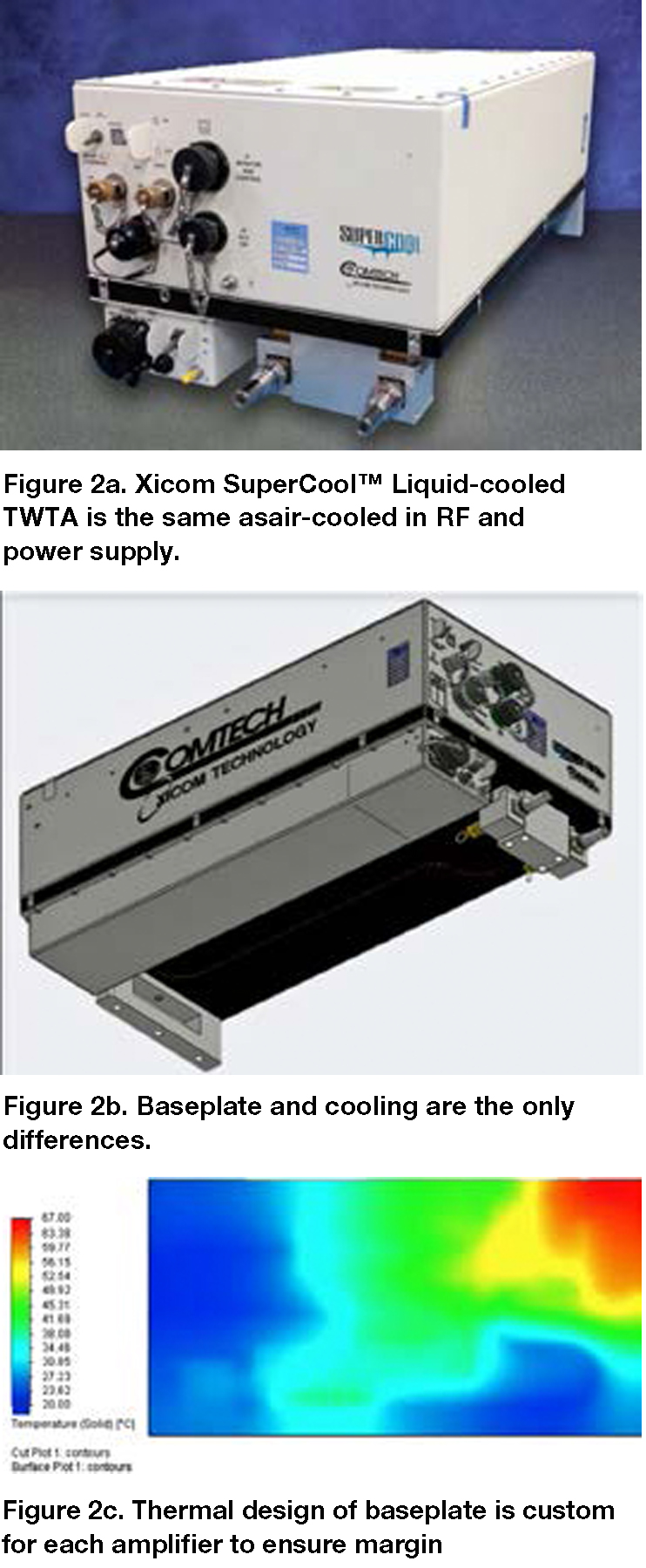

These new liquid-cooled HPAs (see Figures 2a through 2e) are identical to the standard air-cooled TWTAs except for replacing the standard baseplate, fins, fans, and ducting with a new baseplate containing the tube which carries the cooling liquid through the plate (Figure 2a).

This makes it easy to create the new liquid-cooled product from an existing one, simplifying material management and manufacturing, while also keeping complete isolation of the cooling liquid from the RF and power supply electronics which are in separate, sealed compartments (Figure 2b).

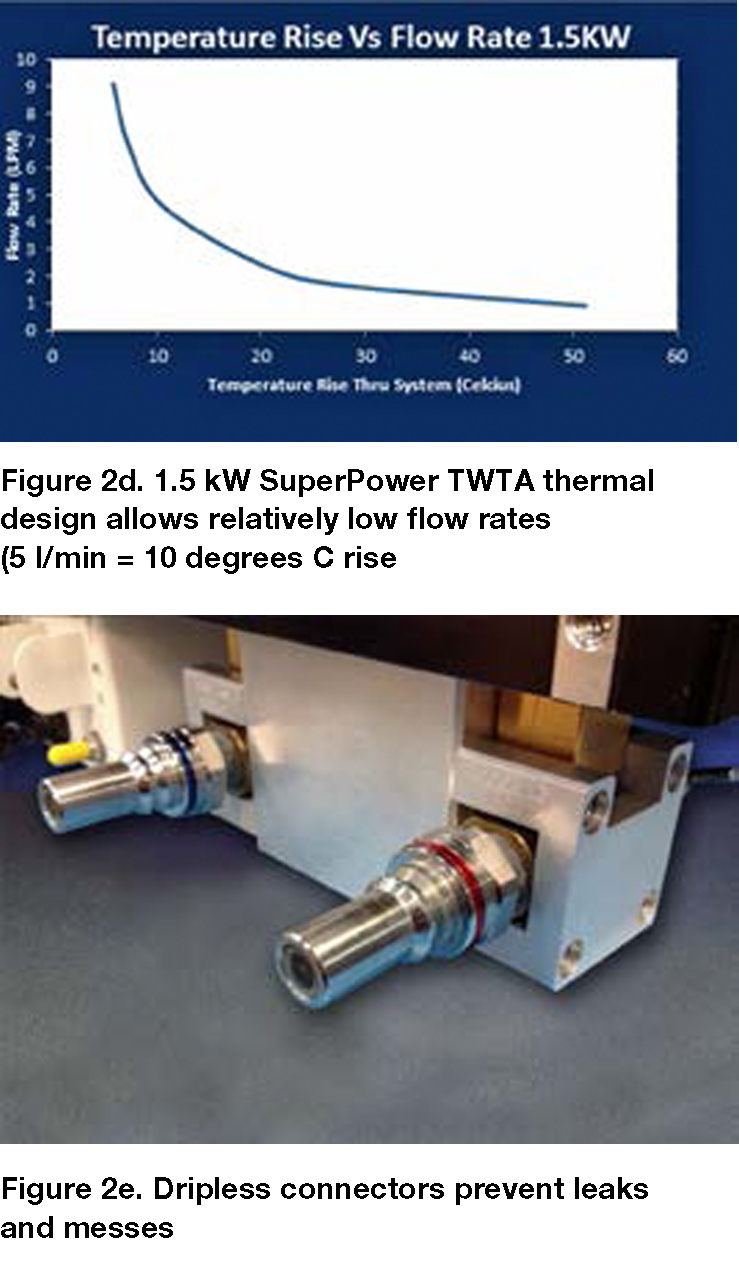

The layout of the tube in the plate is custom designed for the thermal dissipation of the specific amplifier model (Figure 2c), and is designed with margin to comfortably cool the TWTA with a fairly low flow rate (Figure 2d).

The ends of the cooling tube are connected to a pair of dripless connectors which are color coded for the input and output of the unit (Figure 2e).

Figure 3a. Above-ambient liquid-to-air heat exchanger.

These do not leak even when disconnected under pressure, and they connect to matching color-coded mating connectors attached to hoses to and from the rest of the cooling system.

There are many approaches to the overall cooling system described in detail in the System Design section. These easy to use and implement liquid-cooled TWTAs offer a host of benefits to the system designer including:

• No interaction of liquid with RF or power supply electronics

• Fool-proof dripless connectors that click to connect, are color-coded, can be disconnected under pressure drip-free, and are easily replaced if needed

• Efficient amplifiers and thermal design for low flow rates allow for low cost and easily available pumps

• Baseplate temperature monitoring in critical spot for feedback to loop flow control

• Easy upgrades to replace air-cooled HPAs—same waveguide to mounting points; only changes are new cooling liquid interfaces and no air low requirements

Figure 3b. Refrigerated liquid-to-air chiller.

Cooling System Design

The HPA is only one part of the cooling system; the rest can vary widely depending on the installation location, available resources, and constraints. Many larger facilities have chilled water on site for air conditioning, and a small portion of the chiller’s capacity can be used to cool the HPAs.

Other terminals will require a dedicated liquid-to-air cooling system. These dedicated systems can be implemented as either above ambient heat exchangers (Figure 3a) or as temperature controlled chillers (Figure 3b).

The heat exchangers have no refrigeration cycle and are therefore simpler, more economical, and easily controlled. Most applications for the new liquid-cooled HPAs can easily work with a simple heat exchanger. However, they have a limited cooling capacity, especially in cases where the ambient air temperature is relatively high.

For these cases, a refrigerated chiller may be selected to allow for maintenance of the baseplate temperature much closer to the ambient air temperature. These systems are more complicated, cost more, and may require more maintenance. However they can still be quite compact, as they can support a wider temperature range of operation.

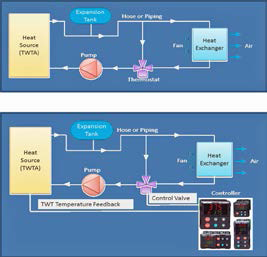

Figure 4 (top). Passive control liquid cooling systems are simple and economical

Figure 5 (above). Active control valve modulation liquid cooling systems are higher performing.

There are two primary dedicated cooling system types.

Cooling systems can be controlled passively with a thermostat which measures the liquid temperature and adjusts flow through the heat exchanger to maintain the desired temperature of the coolant (Figure 4).

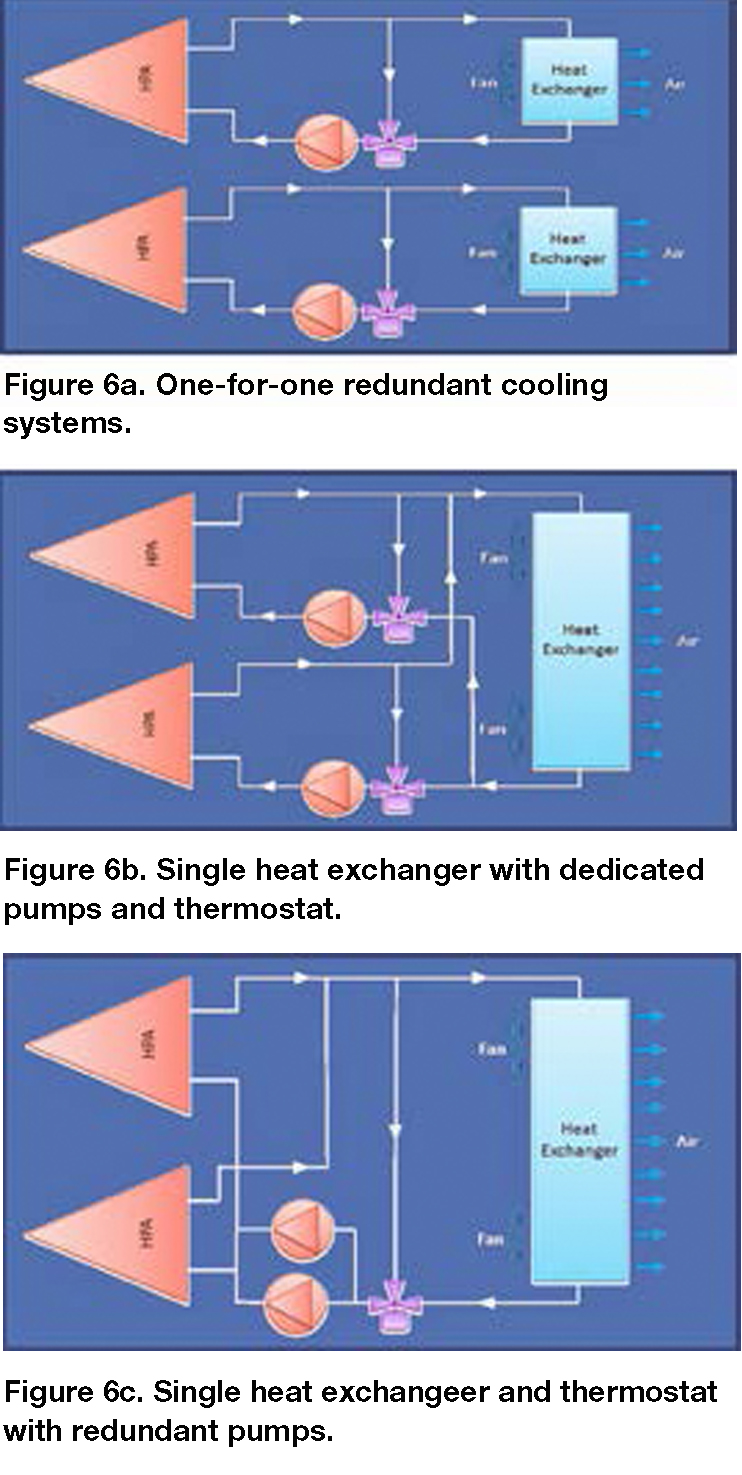

Common redundancy options for cooling systems.

This approach using all passive components is similar to automotive engine cooling systems, and is both simple and economical. The primary alternate of active control valve modulation (Figure 5) uses a controller and more precise temperature feedback available from the critical portion of the HPA to control the valve that adjusts how much of the liquid passes through the heat exchanger. Active control requires some additional engineering but provides better temperature control of the TWTAs RF components.

There are many redundancy options for liquid cooling systems, and each system designer must consider their availability and maintainability requirements along with operational considerations when choosing one.

The basic 1 for 1 redundant system (Figure 6a) provides a separate cooling system for each of two redundant HPAs. This requires no complex design, but does not lower cost through shared elements or improve system reliability through shared redundant systems.

For sharing of one of the larger elements in the system, a single heat exchanger can be used for both HPAs while maintaining dedicated pumps and thermostats (Figure 6b). This can reduce the system’s space and cost without impacting reliability.

Further consolidation and improved redundancy can be accomplished by tying redundant pumps together with a single heat exchanger and thermostat (Figure 6c) so that either pump could support operation of either HPA. Thus, some additional plumbing improves availability.

Cooling System Equipment

The key types of equipment in the above-ambient heat exchanger type cooling systems are widely available and not expensive. There is a lot of flexibility in the available equipment to adapt to the requirements of any implementation such as high pressure needed for pumps installed a long distance from or well below the operational HPAs.

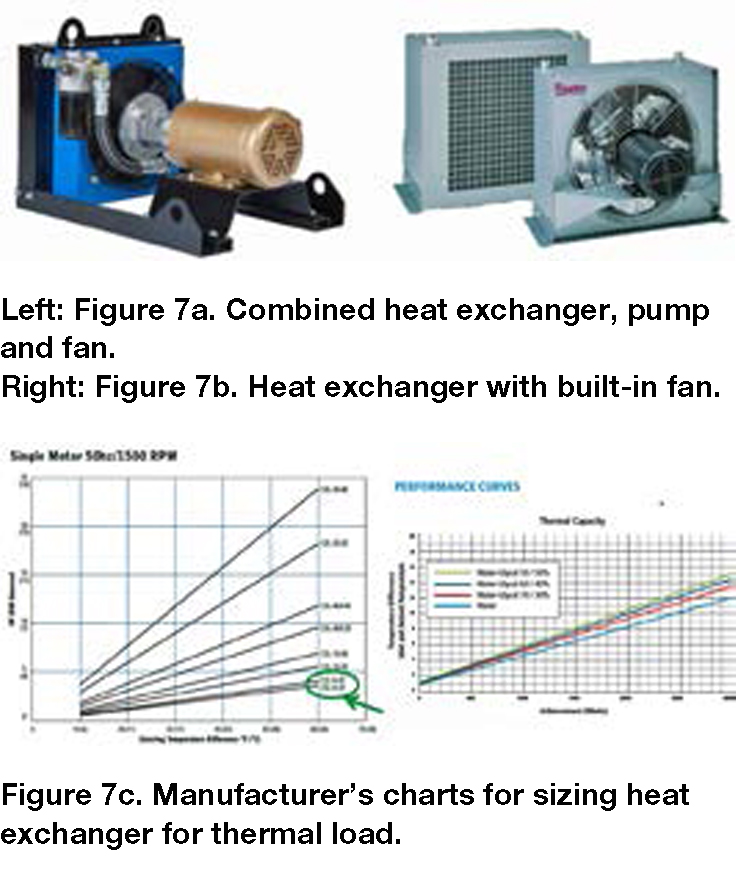

Available heat exchanger types easily handle HPA thermal loads.

Available heat exchanger types easily handle HPA thermal loads.The heat exchangers specifically can be indoor or outdoor rated for placement near the hub either in a shelter or out of doors, and are available in sizes rated to thermally dissipate from 1 to over 10 kW. Heat exchangers can be purchased in combinations including integrated fans or even integrated pumps as well (Figure 7a and Figure 7b).

The exchangers come in standard sizes, and must be selected for the thermal load (HPA), but the manufacturers provide easy to read charts to support this (Figure 7c).

HPAs are at the low end of standard thermal loads for these; a typical TWTA could be cooled with a standard combined exchanger size of 13x16x27 inches.

Pumps for cooling systems have improved significantly and are built for reliability. Available pumps have magnetic drive to eliminate bearings as a failure item and have no shaft seals to increase MTBFs. There are pumps with high flow rates available for applications with multiple HPAs, and there are pumps with high head pressure to support long distances between the heat exchanger and the HPA and also heat exchanger locations well below HPAs (Figure 8).

Drip-free connectors are one of the most exciting advances in these cooling systems (Figure 9).

Left: Figure 8a. Magnetic drive high flow rate pump. Right: Figure 8b. Magnetic drive high head pressure pump

Available pump types and capability offer flexibility for different applications.

These connectors have been designed to allow easy, no-tool connect/disconnect for quick HPA changeout, and are dripfree even when disconnected under pressure.

This eliminates spillage during installation and service without any extra time for the technician.

They are available with hose barb or NPT thread interfaces for use with hoses and pipes, and there are even rotating joints available for connection to rotating assemblies such as full motion antennas.

Finally, connections between cooling system elements are typically a combination of piping and hoses to adapt to the implementation.

There’s a large range of flexible hoses from the hydraulics industry that handle a wide temperature range and include UV rated offerings for outdoor installations.

Figure 9. Drip-free connectors make connections fast, clean and reliable.

Rigid piping is typically used for longer distances and support. Metal piping provides greater support at greater cost while plastic piping costs less and is easier to work with—but provides less support

Depending on site requirements, rigid piping can be buried or above ground, and can run long distances—10’s or 100’s of meters—for which you can use insulated piping to reduce impact on heat exchanger thermal load.

Liquid-Cooled HPAs Are Here To Stay

The many significant advantages of liquid-cooled SuperCool TWTAs make it straightforward to decide to use liquid-cooling in new terminals that have large RF power requirements, and make it a viable option for existing terminal upgrades.

Figure 10. A wide range of pipes and hoses are available for installation flexibility.

Whether to reduce or eliminate maintenance issues, simplify hub design, eliminate a large thermal load from indoor HPAs, or reduce noise in your neighborhood, you will probably find yourself thinking about using these.

Whatever your reason for wanting to look at liquid cooling, white papers on reference cooling system design and additional technical support

are available.

The cooling system equipment needed is readily available and not costly, so expect to see more and more teleports and gateways implementing liquid-cooled HPAs in the near future.

xicomtech.com/

Mark Schmeichel, Vice President of Engineering and Technology at Comtech Xicom Technologies with 20+ years experience in RF amplifier, RF systems, Electronics, Power Electronics and Mechanical Engineering, in the Telecom and SATCOM Industries with Motorola, Andrew, MCL (Miteq), Teledyne, and Comtech Xicom. BSME Northern Illinois University

Heidi Thelander, Senior Business Development Director at Comtech Xicom Technology with 20+ years experience in satellite systems and hardware design for space and ground, program management and business development for space and ground systems and RF amplifiers, working for large system integrators and start-ups, including TRW (now Northrop Grumman), Lockheed Martin, Centerpoint Broadband, Wavestream, and Comtech Xicom Technology. BSEE Marquette University, MSEE in Communication Systems, University of Southern California.