The space industry is inherently challenging so delays and schedule changes are considered a common occurrence. While launch vehicle providers and satellite developers are becoming more consistent and efficient, the industry still faces delays that can have costly impacts on missions and the industry at large. Delays from launch vehicle providers cost satellite developers time and money while delays on the satellite side can cause payloads to miss their ride to space altogether.

In order to minimize the negative impacts of delays, the industry needs to create innovative solutions that will increase flexibility, enabling satellites to easily move from one launch to another. The ability to change launches can lead to cost savings and schedule assurance for satellite manufacturers while maximizing revenue for launch vehicle providers. In order to do this effectively, the industry needs to streamline satellite integration onto launch vehicles.

Standardized Structures, Avionics and Interfaces

While the concept of standardization isn’t new, much needs to be done to improve the hardware and integration processes for rideshare missions.

Currently, each launch vehicle and spacecraft have custom designs that require the integration of the two pieces of equipment to be uniquely tailored. This approach inhibits the efficiency and flexibility for rideshare.

Structures, such as the ESPA ring and its derivatives, have contributed to the standardization of interfaces, packaging, and the integration process; however, to improve flexibility, it’s important to begin development of similar hardware systems by vehicle class.

For instance, small launch vehicles require more mass-optimized structural systems when compared to large launch vehicles, where mass and volume is less of a factor.

Similar component needs still exist between large and small vehicles, and integrators can leverage these wherever possible.

Creating common families of rideshare-oriented avionics and structures across all launch vehicles will be most beneficial, as this approach minimizes the unique hardware required on each mission, resulting in cost savings which can be passed to the customer. Familiar equipment also enables engineers and integration teams to develop greater expertise with the hardware and integration processes.

Creating standard structures, avionics, and interfaces for rideshare is challenging as each satellite is uniquely designed and implements different interface hardware.

There are good examples where the industry has chosen to standardize, such as the cubesat standard, though much can be done to improve.

Cubesats are, in general, a standard shape and size, which makes the integration process predictable, efficient, and flexible. Because of this, cubesats can be rescheduled on a new launch as late as two or three months before a mission.

Changing a launch for a microsatellite can, and has, been done; however, their varying sizes, weights, shapes, and requirements quickly decrease the window of opportunity to execute a manifest change.

Enabling flexibility for microsatellites will require a standard of some sort to be adopted that improves interchangeability. This standard could initially focus on satellite mass and volume categories that are linked to separation system size, though many other factors must be addressed.

This will enable integrators to match new satellites to standard interface systems and move satellites between vehicles more quickly and efficiently.

Create Interchangeable Launch Analyses

Rockets are configured to maximize performance for every launch. There is very little margin for error. Thus, in order to ensure the success of every launch, extensive analyses are required.

Unique mission analyses are resource intensive and whenever a change is made to the manifest, some analyses are invalidated and require rework.

This approach of mission unique analyses does not encourage the movement of payloads and frequently results in delays to the launch schedule.

Thorough analyses are a critical aspect of the integration process and will never be completely eliminated, but it is important to seek opportunities that eliminate inefficiencies associated with the standard launch analysis cycle.

There are programs and technologies that can assist in improving the analyses conducted prior to each launch. Some analyses should be run earlier in the launch process, creating bounding cases wherever possible.

This will limit analysis churn when a launch manifest changes, and provide quick-turn capabilities to assist in remanifesting satellite customers. By reducing the analysis load on each manifest change, launch flexibility will improve.

Establish Rideshare Integration as a Standardized Service

Launching satellites, especially in rideshare scenarios, is a study in opposing requirements. Satellites are delicate, but to get them on orbit, they are subjected to extreme environments by the launch vehicle.

The contrast between the power of a rocket and the fragility of a satellite makes the process of bringing the two together complex and critical.

Marrying rockets and satellites together goes beyond simply bolting a payload down for the ride. If a payload on its separation system is not integrated properly, it can be destroyed before the rocket reaches orbit or not deploy successfully once on orbit. The need for engineers, mission managers, and integrators to understand both the rocket and satellite requirements is paramount.

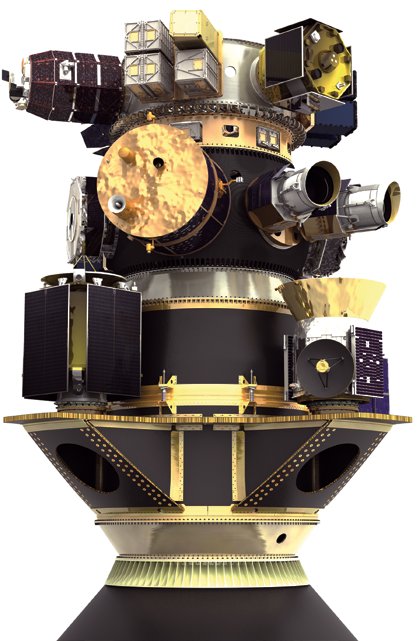

(Image: SSO-A stack.)

Understanding these needs benefits the industry greatly allowing creation of processes that minimize risk to interface a delicate spacecraft with the launch vehicle, increasing likelihood of mission success

for both the launch provider and the satellite developer.

Standardizing launch services through rideshare integrators provides systems that minimize the risk of spacecraft damage while working to translate all of the needs between satellite and launch vehicle personnel.

This allows the launch vehicle provider to focus on their mission — getting to orbit; it also allows the rideshare spacecraft to focus on what they do best — execute their orbital mission.

Though space will always present challenges and complications, this relatively young, innovative, and evolving industry is well-positioned to change processes and adopt solutions that will

improve efficiency.

The space industry experiences frequent changes, and by seeking ways to increase flexibility, some pains that result from these changes can be eliminated. Integration service providers will be a key element in achieving this flexibility, which will contribute to the growth of the entire

smallsat industry.

https://spaceflight.com

Philip Bracken is the director of engineering at Spaceflight, Spaceflight Industries’ launch services and mission management offering. Philip oversees a diverse team of engineers and technicians that support all of Spaceflight’s rideshare and dedicated rideshare missions.

Before joining Spaceflight, Philip was a principle manager and liquid propulsion engineer at Blue Origin, responsible for liquid engine and upper stage design and development activities. Prior to that, he worked at Orbital ATK (now Northrop Grumman Innovative Solutions) supporting multiple launch vehicle and satellite development programs.

Philip received his Bachelors in Aerospace Engineering from Rensselaer Polytechnic Institute and is pursuing advanced studies with Purdue University.