Some 7,000 satellites have flown on orbit during the 60 years since Sputnik was launched.

Recently, several companies have filed FCC applications with their goal being the launch of more than 30,000 new satellites during the next five years.

By leveraging miniaturization, commercial off-the-shelf technology, and mass-manufacturing techniques, companies are changing the economics of satellite missions to enable ambitious projects that previously were not possible. One of the key components of this new generation of constellations is the satellite propulsion system.

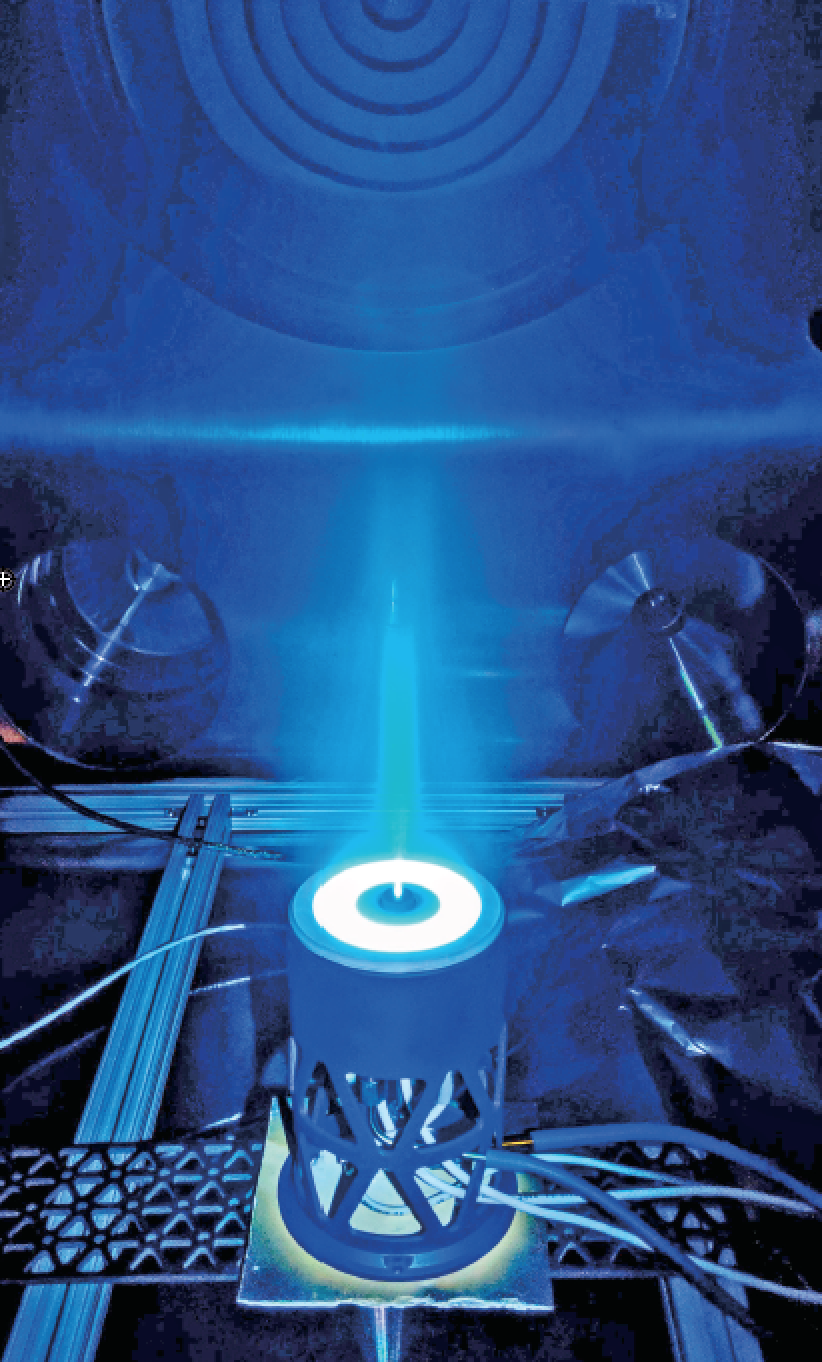

New developments with Hall thrusters are introducing major improvements which significantly reduce volume and mass while providing the performance for demanding missions.

These innovations are creating a significant number of commercial opportunities for imaging, synthetic aperture radar, and telecommunications satellites, and everyone wants to be first to the market.

2018 is the first year new propulsion systems will change the trade space. The teams designing the new class of constellations face many challenges. Engineers and scientists must design a satellite that meets tough performance requirements. The goal is a satellite that is priced low enough to make the constellation profitable and that can be launched in larger numbers, at a faster rate than ever before possible.

Once the satellites are launched, the operators must move these satellites to their correct orbit, constantly monitoring and adjusting the positions of all satellites in the constellation to avoid collisions with the ever increasing number of satellites and debris in orbit. Until now, the satellite propulsion systems placed major constraints on the sizes of the satellites themselves.

Historically, propulsion systems have been bulky, expensive, and manufactured “by hand.” Traditional chemical propulsion systems could occupy as much as 50 percent of the satellite’s volume and mass in order to boost the satellite into the proper orbit. In the last several decades, the much more efficient electric propulsion systems (ion propulsion and Hall Effect Thruster systems) have helped reduce the mass and volume fractions to 30 percent of the satellite mass and volume.

In the last couple of years, several new companies (including Apollo Fusion) have been developing even more compact electric propulsion systems — these would occupy a mere 10 percent of the mass and 5 percent of the volume of a satellite by taking advantage of better thruster efficiencies, smaller electronics as well as novel propellants.

When every kg. of mass launched into space costs as much as the price of gold ($15,000/kg.), every gram counts!

The extra mass and volume savings of a satellite achieved by switching to a higher performance propulsion system results in less expensive satellite price tags, or more space for revenue-generating payload — or both.

With smaller and more powerful propulsion systems, teams are now considering the advantages of flying in the lowest possible orbit.

Telecommunications and Earth imaging companies are deploying vast constellations. Some will use propulsion systems to efficiently maintain altitude in orbits lower than ever before experienced.

These lower altitudes mean faster data rates for telecommunications missions and increased resolution for Earth imaging. For these new missions, improved propulsion systems can boost the key drivers of revenue growth — imaging resolution and mission duration.

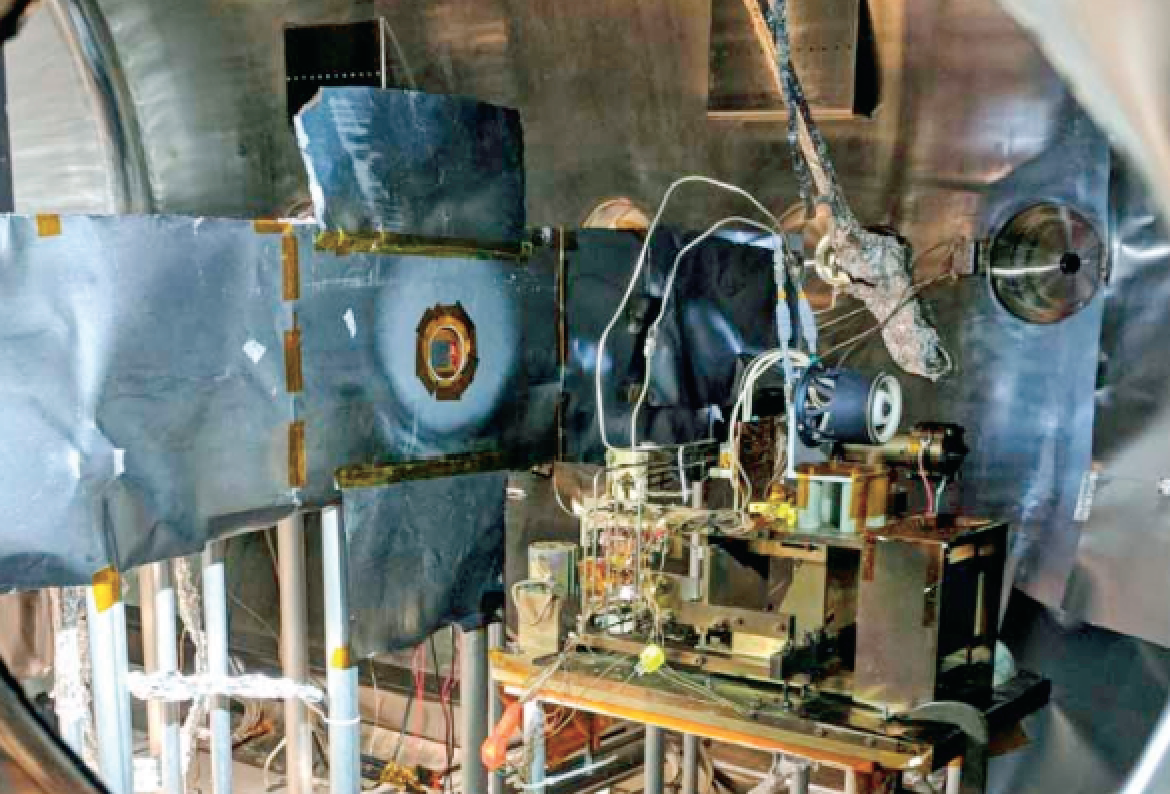

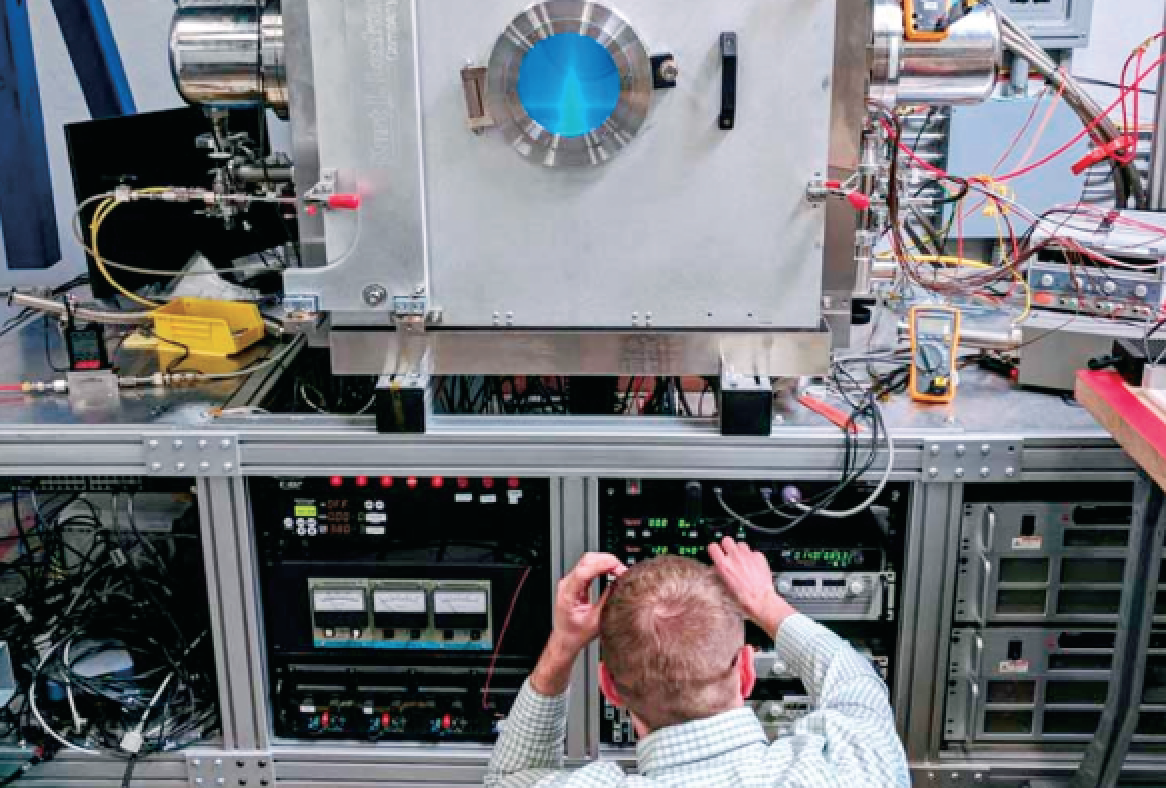

Apollo recently tested their ACE thruster in an independent lab at The Aerospace Corporation where thrust, Isp, and efficiency measurements closely matched Apollo’s own lab tests. These results confirmed that ACE has 3x better impulse per kg and 3x better impulse per liter than competing thrusters.

For telecommunications satellites, LEO altitudes can reduce the distance between satellite and customer by half. By positioning the satellite 20 times closer to the customer than a GEO satellite, data rates can be as much as 400 times higher, resulting in reduced latency and greater revenue potential.

Earth imaging satellites like to fly as low as possible, increasing their image resolution. However, at such low altitudes (300 to 350 km) satellites are at risk of being pulled into the Earth’s atmosphere and burning up within weeks after their launch.

Previously, engineers designing Earth imaging satellites had two options: increase the optical aperture size to increase image resolution at higher altitudes or fly lower and use chemical propulsion to maintain altitude for years.

Vibration tests at Quanta Laboratories were designed to exceed the loads experienced by satellites on eight popular launch vehicles. With random and sine loads up to 13 G’s, ACE withstood the harsh conditions and passed all tests without damage.

Both of those options are expensive. Increasing aperture size is one of the more expensive hardware upgrades an observation satellite manufacturer can make.

Chemical propulsion systems are also expensive and there’s also the additional cost of a losing a satellite once the chemical propellant runs out after only a year on orbit — long before the satellite is considered obsolete.

Engineers may now select to use high performance Hall thrusters to maintain an imaging satellite’s altitude at 300 to 350 km. for approximately five to seven years. This allows Earth imaging satellites to double their resolution at one-fifth the cost of increasing the aperture size.

In 2018, attaining GEO will become far less expensive and faster to implement an orbit.

Manuevering from LEO to GEO orbit.

Other satellites with GEO missions have, until now, been locked into expensive GTO launch options with less frequent and less flexible launch schedules.

Using Apollo Fusion’s four test chambers, the team completed a series of lifetime tests using three different types of propellant over hundreds of hours of operation including hundreds of start/stop cycles. Results indicate reliable performance and an operational lifetime expected to exceed 4,000 hours.

For these GEO satellites, compact, high thrust electric propulsion systems can significantly reduce launch costs (by at least $5 million for some satellites) and accelerate schedules by enabling mission planners to select a LEO launch and to use electric propulsion to move satellites from LEO to GEO. Many constellations are expected to take advantage of this capability to reduce their launch costs.

With these innovations, satellite manufacturers can now do things that were previously never possible.

2018 promises to be the year that economical satellites make their orbital debut, enabled by higher performance propulsion systems, smaller COTS electronics and reduced launch costs.

apollofusion.com

Ben Longmier holds advanced degrees in Physics, Nuclear Engineering, and Plasma Physics, is a former professor at the University of Michigan, and was the founder and CEO of an aerospace company which was acquired by Apple.